With reference to risk assessment and the Code of Safe Working Practices for Merchant Seamen:

(a) explain the purpose of a risk assessment;(4)

(b) state the person responsible for carrying out the risk assessment;(3)

(c) outline what should be considered when carrying out a risk assessment.(3)

With reference to the Code of Safe Working Practices for Merchant Seafarers and entering enclosed or confined spaces, state EACH of the following:

(a) the reasons why the atmosphere of any enclosed space is potentially dangerous;(4)

(b) the precautions to be taken before a potentially dangerous space is entered.(6)

- Outline the FOUR duties of workers as laid down in the Code of Safe Working Practices for Merchant Seamen.

(10)

- With reference to dangerous (enclosed) spaces onboard a vessel:

(a) state FOUR different examples;

(b) explain why the atmosphere may be dangerous.

10

(4)

(6)

- Outline the procedures and arrangements to be put into place before a permit to work is issued for entry into a confined space.

(10)

With reference to the International Safety Management code, describe EACH of the following:

(a) the Safety Management System (SMS);(5)

the role of the Designated Person (DP).

Quiz Hotel Service Unit 2 Safety Q1

Explain EACH of the following:

(a) Merchant Shipping Notices;(4)

(b) Marine Guidance Notes;(3)

(c) Marine Information Notes.(3)

Quiz Hotel Service Unit 2 Safety Q2

- With reference to the SOLAS requirements for conducting regular emergency musters and drills:

(a) state the accepted emergency signal for calling crew and passengers to lifeboat muster stations;(2)

(b) state when emergency drills must be carried out;(4)

(c) list FOUR types of emergency drill that must be conducted on a regular basis.(4)

Quiz Hotel Service Unit 2 Safety Q3

- With reference to noise levels in ships:

(a) describe the recommended maximum periods of time for personnel employed on watchkeeping duties within enclosed machinery spaces;(6)

(b) explain why these recommendations have been made;(2)

(c) state the permitted noise level at which hearing protection is:

recommended;(1)

(ii) mandatory.(1)

Quiz Hotel Service Unit 2 Safety Q4

9.List FIVE safety devices that may be fitted to the main swichboard of a vessel, stating reasons for fitting each device.

(10)

Quiz Hotel Service Unit 2 Safety Q5

- (a) State, with reasons, where the watch should be handed over on a vessel fitted with a UMS system, where the period of duty is 24 hours.(2)

(b) Outline the responsibility of the duty engineer with respect to EACH of the following:

(i) the Systems Status Board;(3)

(ii) the Oil Record Book;(3)

(iii) the main and auxiliary Machinery Maintenance Record Book.(2)

- With reference to unmanned machinery spaces:

(a) explain why machinery spaces should be visited on a regular basis;(2)

(b) explain how the human senses are used to monitor conditions in a machinery space;(4)

(c) outline the procedure to be adopted if a person wishes to enter a machinery space outside normal working hours.(4)

- With reference to routine inspections of machinery located in remote unmanned spaces:

(a) state FOUR precautions that should be taken to ensure the safety of personel;(4)

(b) state FOUR notices that should be posted at the entrance of unmanned machinery spaces;(4)

(c) define the meaning of the term Machinery Space.(2)

- Describe the method of testing EACH of the following:

(a) a bilge high level alarm switch;(3)

(b) a diesel engine cooling water high temperature alarm probe;(3)

(c) an oil mist detector.(4)

State the action to be taken by the watch keeping engineer in the event of EACH of the following:

(a) flooding;(6)

(b) failure of main propulsion machinery. (4)

List FIVE statutory items that the relieving officer shall be informed of by the officer in charge of the engineering watch prior to taking over the engineering watch. (10)

- Describe the responsibilities of the off-going duty engineer with respect to EACH of the following:

(a) fuel service tanks;(2)

(b) oily water separator;(2)

(c) potable water tanks;(2)

(d) machinery space defect book;(2)

(e) main engine sump level.(2)

- With reference to the engine log books, explain the reasons for recording EACH of the following:

(a) running hours;(2)

(b) lubricating oil consumption;(2)

(c) fuel consumption;(2)

(d) salanity or chloride content of the engine jacket cooling water;(2)

(e) water content of lubricating oil.(2)

- With reference to the engine room log book:

(a) state THREE reasons for keeping such a log book;(6)

(b) state EACH of the following:

(i) the person responsible for its compilation;(1)

(ii) the interval at which it should be written up and signed;(1)

(iii) the procedure to be followed if a correction of entry is required;

(1)

(iv) the purpose of recording a general abstract for main and auxiliary engines.(1)

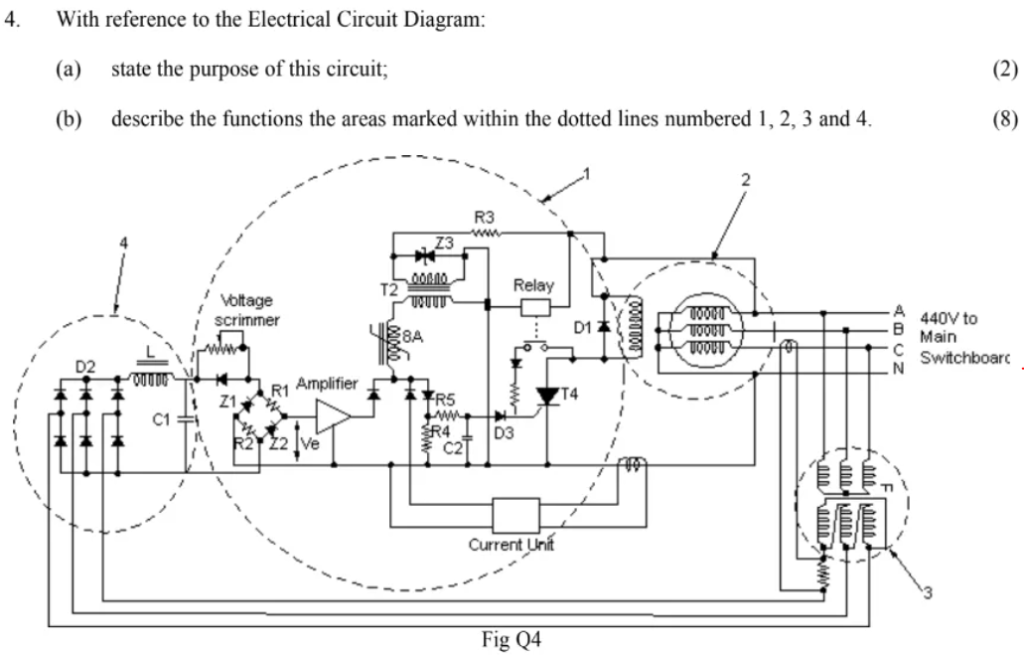

2.

(a) State THREE reasons for keeping a log.(6)

(b) State the person responsible for compiling the log.(1)

(c) State when the log should be compiled and signed.(1)

(d) Describe the action to be taken should a mistake be made during writing up the log.(2)

- With reference to the engine log books, explain the reasons for recording EACH of the following, and the effect on the engine should the temperatures be outside the normal parameters:

(a) exhaust temperatures;(3)

(b) cooling water inlet/outlet temperature;(3)

(c) lubricating oil temperature.(4)

- With reference to the engine log books, explain the reasons for recording EACH of the following, stating a possible cause should the readings be outside the normal parameters:

(a) LO Sump level;(4)

(b) cooling water inlet temperature;(3)

(c) inlet manifold air pressure;(3)

- List TEN common log entries, excluding machinery temperatures, pressures and other parameters.(10)

3.(a) State the purpose of a planned maintenance system.(4)

(b) State THREE parameters on which planned maintenance may be based.(3)

(c) State how an approved planned maintenance system can influence classification society requirements.(3)

- With reference to maintenance systems:

(a) state the purpose of scheduled maintenance;(4)

(b) explain why unscheduled maintenance may be required even if a scheduled maintenance system is in operation;(4)

(c) state why breakdowns should be kept to a minimum.(2)

3.

(a) State THREE advantages of using condition monitoring as part of a planned maintenance system.(3)

(b) State THREE examples of criteria that could be used as a basis for condition based maintenance.(3)

(c) State FOUR reasons for keeping records of operating criteria and planned maintenance carried out.

- With reference to maintenance and maintenance systems:

(a) state SIX reasons for keeping records;(6)

(b) explain the advantages of an approved maintenance system.(4)

- With reference to marine diesel oil:

(a) define EACH of the following terms, stating the unit used in EACH:

(i) density;(2)

(ii) viscosity;(2)

(iii) flash point.(2)

(b) excluding the THREE terms listed in part (a), state FOUR items of information contained on a Bunker delivery note.(4)

- With reference to bunkering of marine diesel oil:

(a) state THREE possible consequences of water contamination of the fuel;(3)

(b) state THREE sources of contamination of fuel by water on board a vessel;(3)

(c) describe TWO separate tests which would indicate the presence of water in the fuel.(4)

- With reference to bunkering of marine diesel oil:

(a) explain why the suppliers’ tanks should be dipped prior to and after receiving fuel;(4)

(b) explain what is meant by a letter of protest, and when it must be issued;(4)

(c) state the person responsible for issuing the letter of protest.(2)

- With reference to microbiological contamination of marine gas oil:

(a) state the conditions that must be present for the microbes to live and multiply,(2)

(b) describe the effect of microbiological growth in the fuel;(2)

(c) explain how the contamination may be detected;(2)

(d) state how the risk of contamination may be reduced;(2)

(e) explain how the contamination may be removed.(2)

- With reference to the safe bunkering of marine gas oil fuel:

(a) list SIX actions that should be taken prior to and during the loading;(6)

(b) state FOUR tests to be carried out on the fuel to ensure that it is uncontaminated.(4)

(a) State FOUR possible contaminants that may be present in marine gas oil.(4)

(b) Describe a means of dealing with THREE of the contaminants listed in part (a).(6)

- With reference to the international agreement governing the discharge of oil from ships:

(a) state the name of the International Authority responsible for overseeing the legislation;(1)

(b) state the name of the appropriate regulation;(1)

(c) state what the abbreviation SOPEP stands for;(2)

(d) explain the purpose of a SOPEP;(2)

(e) list FOUR items of information a SOPEP should contain.(4)

- (a) State the main pollutant produced when burning a hydrocarbon fuel.(1)

(b) Explain how the pollutant referred to in part (a) can be reduced.(2)

(c) State what is meant by an ECA.(1)

(d) State the current maximum % sulphur content in marine diesel oil in EACH of the following:

(i) worldwide;(1)

(ii) in a ECA.(1)

(e) Describe how SO, is produced in the combustion process and the effects oxides of sulphur has on the environment.(4)

- List FIVE precautions to be observed before taking on bunkers, stating a reason for EACH precaution.(10)

- With reference to bunkering fuel oil, list the actions that should be taken if a spillage occurs.(10)

5.(a) State the MARPOL Annex number which deals with the disposal of sewage.(1)

(b) With reference to the Annex stated in part (a), state the rules for EACH of the following:

(i) when the sewage is untreated;(2)

(ii) when the sewage is comminuted and disinfected.(2)

(c) Explain why the final discharge from an approved sewage treatment plant is chlorinated before discharge.(2)

(d) Explain how chlorination is carried out and monitored.(2)

(e) State the correct chlorine content of the final discharge.(1)

6.With reference to sewage treatment plants:

(a)

state the purpose of the vent, and explain why it is fitted with a gauze;(3)

(b) explain the difference between aerobic and anaerobic micro organisms;(3)

(c) explain why air is bubbled through the effluent in the aeration tank;(2)

(d) explain why calcium hypochlorite is added to the treated sewage before discharge overboard.(2)

- With reference to sewage treatment plants:

(a) describe the biological operating principle of an aerobic sewage treatment plant, explaining the dangers if a supply of oxygen is not present;(8)

(b) state how a sufficient supply of oxygen is ensured.(2)

- (a) State the IMO regulations for the disposal of sewage.(4)

(b) With reference to aerobic sewage treatment plants, explain EACH of the following:

(i) why air is bubbled through the effluent in the aeration tank;(2)

(ii) why care must be taken over the choice of toilet cleansers used;(2)

(iii) why calcium hypochlorite is added to the treated sewage before discharge overboard.(2)

5.(a) With reference to sewage treatment systems, explain EACH of the following terms:

(i) aerobic;(2)

(ii) anaerobic.(2)

(b) Sketch a Biological Sewage Treatment Plant, labelling the MAIN compartments and indicating the direction of flow through the plant.(6)

- With reference to sewage treatment plants:

(a) explain the difference between black water and grey water;(2)

(b) explain the difference between aerobic and anaerobic micro organisms;(3)

(c) list THREE dangerous gases produced under anaerobic conditions;(3)

(d) explain the dangers of producing the gases listed in part(c) in a confined space.(2)

- (a) State the THREE main stages of a Biological Sewage Treatment Plant.(3)

(b) Describe the operation of a Biological Sewage Treatment Plant, explaining the process carried out in EACH of the stages stated in part (a).(7)

6.(a) With reference to MARPOL Annex IV, explain what is meant by the term sewage.(4)

(b) State the current regulations for the discharge of sewage.(6)

- With reference to sewage treatment plants:

(a) describe the biological operating principle of an aerobic sewage treatment plant, explaining the dangers if a supply of oxygen is not present;(8)

state how a sufficient supply of oxygen is ensured.(2)

- Explain, with the aid of a sketch, how an Aerobic Sewage Treatment plant operates.(10)

Hotel Service Unit 10 Q10 Quiz

- Describe the operation of a Biological Sewage Treatment Plant.(10)

Hotel Service Unit 10 Q11 Quiz

- (a) With reference to food storage rooms:

(i) state, with reasons, the possible danger present in a room used for storing vegetables and fruit;(2)

(ii) state the devices necessary to prevent a person from becoming trapped in a storage room.(3)

(b) State FOUR methods of detecting a refrigeration gas leak.(4)

(c) State the name of the international agreement which stipulates that the production and consumption of compounds that deplete ozone in the stratosphere is phased out.(1)

- With reference to safe storage and handling of refrigerant:

(a) state where the refrigerant gas bottles should be stored;(2)

(b) state the weakest part of the storage bottle;(1)

(c) explain how it can be determined if refrigerant has been leaking from gas bottles;(1)

(d) state the TWO methods of recharging a refrigeration system, stating where the connection to the system should be made for EACH method;(4)

(e) state how excessive refrigerant should be removed from the system without infringing MARPOL regulations.(2)

- With reference to refrigeration plants, describe the effects of EACH of the following, stating remedial actions to be taken in EACH case:

(a) undercharge of refrigerant;(3)

(b) air in the system;(3)

water or moisture in the system.(4)

- With reference to refrigeration plant;

(a) state THREE indications of a loss in refrigerant charge;

(b) state THREE methods of detecting the location of the source of leakage;

(c) describe a safe method of bringing the gas charge back to its normal working level.

- With reference to refrigeration systems:

(a) state the THREE basic principles of refrigeration;(3)

(b) sketch a direct expansion free standing mechanical refrigeration system, labelling the MAIN components and indicating where EACH of the three principles stated in part (a) occurs.(7)

- (a) Sketch a vapour compression refrigeration system, labelling the main components.(5)

(b) Indicate the refrigerant conditions at the salient points on the sketch in part(a).(5)

- (a) State FIVE properties of a refrigeration oil.

(b) Describe the operation of an Oil Separator in a refrigeration system.

- (a) Sketch a thermostatically controlled expansion valve for a vapour compression refrigeration system, labelling all components.

(b) Describe the operation of the valve sketched in part (a).

7.(a) State THREE functions of air conditioning.

(b) With referance to air conditioning, explain EACH of the following:

(i) absolute humidity;

(ii) relative humidity;

(iii) dew point.

- With reference to Marine Air Conditioning Systems, explain EACH of the following expressions:

(a) wet bulb temperature(2)

(b) dry bulb temperature;(2)

(c) comfort zone;(2)

(d) psychrometric chart;(2)

(e) relative humidity.(2)

- With reference to the risk of legionella bacteria in air conditioning plants:

(a) state FOUR main areas which are considered to be a breeding ground for the bacteria, outlining a reason for EACH;(8)

(b) describe how the risks of the existence of the bacteria can be reduced.(2)

- With reference to reverse osmosis plants:

(a) describe the sea water pre-treatment process before the water enters the membrane modules;(6)

(b) describe how the purity of the permeate is measured;(3)

(c) state the limits of impurity in the permeate when produced to World Health Organisation Standards.

7.

(a) Describe, with the aid of a sketch, a reverse osmosis plant, from feed water inlet, to product tank, labelling ALL components and showing the position in the system of the monitoring instruments.(7)

(b) Describe the feed water pre-treatment process before the water enters the spirally wound membrane modules.(3)

7

. (a) Describe, with the aid of a sketch, the operation of the silver ion method of water sterilisation.(6)

(b) Describe how Ultra Violet Light can be used to kill bacteria in potable water.(2)

(c) Explain the disadvantages of using Ultra Violet Light as a method of sterilisation, stating how this may be overcome.(2)

- With reference to reverse osmosis plants:

(a) explain the treatment that the feedwater undergoes to prevent blockage of the membranes;(3)

(b) describe how the purity of the water is measured and protected, stating the limits on purity set by the World Health Organisation;(5)

(c) outline the further treatment the permeated water undergoes before it can be used for domestic purpose.(2)

- Describe, with the aid of a sketch, the construction of a spirally wound membrane suitable for use in a Reverse Osmosis water making plant, identifying ALL component parts.(10)

- Explain, with the aid of sketches, the principles of reverse osmosis as a method of producing fresh water.(10)

- Sketch a line diagram of a single pass reverse osmosis plant.(10)

8.(a) State TWO methods of producing fresh water on board an ocean going vessel.(2)

(b) State TWO methods of killing the bacteria which may be present in the water.(2)

(c) Explain the reasons for adding hydrated lime to water produced on board an ocean going vessel.(3)

(d) Outline the procedure to be followed before a fresh water tank is brought back into service.(3)

- With reference to water treatment:

(a) state the treatment required for fresh water taken on from ashore;

(2)

(b) state FOUR properties required for water used for domestic purposes, describing how this may be achieved in EACH case.(8)

- With reference to fresh water treatment:

(a) describe the process for superchlorinating the fresh water system, stating relevant periods, times, and chlorine levels;(6)

(b) explain what is meant by copper staining and the treatment required to prevent it.(4)

6. (a) State THREE types of micro-organisms that may exist in water.(3)

(b) Describe, with the aid of a sketch, the operation of a Silver Ion Sterilizer.(7)

- With reference to portable fire extinguishers:

(a) describe the examination and testing of portable fire extinguishers as specified in the UK and Internatinal legislation.

(6)

(b) state the classes of fire that Dry powder extinguishers may be safely used;

(2)

(c) describe the operation of a portable CO, fire extinguisher.

(2)

- Define EACH of the following, stating an example in EACH case where a fire could be caused:

(a) spontaneous combustion;

(4)

(b) flash point;

(3)

(c) auto ignition temperature.

(3)

- (a) Define EACH of the following:

(i) Flash Point;

(ii) Ignition Point

(iii) Auto Ignition Temperature.

(2)

(2)

(2)

(b) Explain the requirements for the discharge of CO₂ of a machinery space fixed firefighting installation with regard to volume and time.

(4)

- With reference to a machinery space carbon dioxide smothering system:

(a) state the regulation regarding the rate of flooding with respect to time;

(4)

(b) state the precautions to be taken before activating the system.

(6)

- (a) Explain the need for fitting, location, and operation of an engine room fire main isolation valve.

(4)

(b) State the type of valve used in part (a).

(1)

(c) Describe, with the aid of a sketch, the construction of a sprinkler head.

(5)

- (a) Describe, with the aid of a sketch, how a pressurised system sprinkler head is constructed.

(5)

(b) Explain the operation of the sprinkler head and bulb assembly described in part (a), stating how the alarm is initiated.

(5)

- Sketch a line diagram of an automatic sprinkler system, labelling the MAIN components.

(10)

9.

(a) State FIVE monthly checks which should be carried out on fire fighting equipment.

(5)

(b) State FIVE yearly checks which should be carried out on fire fighting equipment.

(5)

9. Describe, with the aid of a sketch, a multiple bottle CO, gas system suitable for the protection of machinery spaces.

(10)

- Describe, with the aid of a sketch, the construction and operation of a thermistor type rate of rise heat detector.

(10)

Hotel Service Unit 15 Q10 Quiz

List the important operations that should be included when organising fire drills.

(10)

Hotel Service Unit 15 Q11 Quiz

8.(a) Describe, with the aid of a sketch, the method of attachment of a Bilge Keel to a vessel’s hull, explaining the reason for the longitudinal position of the bilge keel, relative to the hull.(7)

(b) State the advantages and disadvantages of fitting a bilge keel compared with other methods of stabilisation.(3)

- With reference to the motion of a vessel in the water:

(a) list the SIX degrees of freedom, describing the meaning of EACH term;(6)

(b) sketch the position of a bilge keel, describing how it reduces vessel motion.(4)

8.(a) State TWO types of Tank Anti-Roll Stabiliser systems.(2)

(b) State the advantages and disadvantages of a stabilising tank system compared to fin stabilisation.(8)

- Describe, with the aid of a sketch, the construction and operation of an Active Controlled Tank roll damping system.(10)

- Describe, with the aid of a sketch, an active tank stabilisation system.

(10)

- Explain, with the aid of a sketch, the hydrodynamic operation of an Active Fin Stabilizer.(10)

With reference to MARPOL Annex V, garbage record book:

(a) state the type of vessel to which the regulation applies;(1)

(b) list the NINE categories into which garbage is grouped for the purpose of the garbage record book.(9)

- With reference to MARPOL Annex V:

(a) list the THREE recognised complimentary garbage handling techniques;(3)

(b) describe the basic requirements of a Garbage Management Plan;(5)

(c) define what is meant by E-Waste.(2)

- With reference to Oily Water Separators (OWS) and the pumping of bilges, explain EACH of the following:

(a) why a positive displacement pump is preferable to a centrifugal pump as the main bilge pump;(2)

(b) why it is important that the flow rate to the separator is not exceeded;(2)

(c) why the discharge overboard line should be higher than the OWS;

(2)

(d) how detergents used for bilge cleaning can affect the operation of the separator;(2)

(e) why an air release is fitted to the top of the shell of the OWS,(2)

- With reference to Annex 1 of the MARPOL convention, state EACH of the following:

(a) the appropriate system to be fitted on a vessel 400GRT or above;(4)

(b) the documentation required, explaining why it is required;(2)

(c) the information to be recorded when pumping bilges overboard through an oil water separator.(4)

- With reference to Oily Water Separators and the pumping of bilges, explain the purpose of EACH of the following:

(a) a bilge holding tank;(2)

(b) an oil drain tank;(2)

(c) an oil content discharge monitor;(2)

(d) a vacuum breaker;(2)

(e) an oil detection probe.(2)

- With reference to the use of Oily Water Bilge Separators:

(a) state, with reasons, the type of pump which should be used;(3)

(b) explain the effect of the bilge water feed rate on the performance;(3)

(c) explain the purpose of EACH of the following:

(i) a bilge holding tank;(2)

(ii) an oil content discharge monitor.(2)

- Describe, with the aid of a sketch, a single stage static Oily Water Separator designed to meet MARPOL Annex I requirements.(10)

3.(a) State the SIX MARPOL annexes which are currently in force.(6)

(b) With reference to MARPOL Annex VI and Oxides of Nitrogen (NO), state which engines have to comply with the legislation.(2)

(c) State TWO other pollutants that Annex VI is designed to limit.(2)

- With reference to ocean going vessels, define EACH of the following:

(a) trim;(1)

(b) freeboard;(1)

(c) camber;(1)

(d) length between perpendiculars;(1)

(e) length overall;(1)

(f) sheer;(1)

(g) stem;(1)

(h) draft marks;(1)

(i) draft;(1)

(j) depth;(1)

- a State the meaning of EACH of the following terms in relation to a vessel’s size:

(i) gross tonnage;(2)

(ii) net tonnage;(1)

(iii) lightweight;(2)

(iv) deadweight;(2)

(v) displacement.(2)

(b) State the relationship between Lightweight, Deadweight and Displacement.(1)

- With reference to a vessel’s structure, explain the meaning of EACH of the following terms:

(a) beam;(2)

(b) frame;(2)

(c) girder,(2)

(d) beam knee;(2)

(e) stringer.(2)

- Explain the meaning and purpose of EACH of the following terms:

(a) flare;(2)

(b) bulwark;(2)

(c) coaming;(2)

(d) freeing port;(2)

(e) scupper.(2)

- Explain the meaning of EACH of the following terms:

(a) LOA;(2)

(b) displacement;(2)

(c) load line;(2)

(d) draught;(2)

(e) breadth.(2)

- With reference to the construction of a vessel, state the meaning of EACH of the following terms:

(a) sheer;(2)

(b) freeboard;(2)

(c) moulded depth;(2)

(d) moulded draft;(2)

(e) flare.(2)

- Explain EACH of the following types of motion:

(a) roll;(2)

(b) pitch;(2)

(c) yaw;(2)

(d) surge;(2)

(e) heave.(2)

- With reference to the use of Oily Water Bilge Separators, explain the meaning of EACH of the following terms:

(a) turbulent flow;(2)

(b) emulsion;(2)

(c) maximum flow rate;(2)

(d) coalescence;(2)

(e) interface.(2)

10. (a) Explain the meaning of EACH of the following terms:

(i) camber;(2)

(ii) sheer.(2)

(b) Describe how EACH of the terms explained in part (a) improve seaworthiness.(6)

- Describe the immediate action that should be taken in the event of EACH of the following occurring, stating a possible consequence if the action is not carried out:

(a) a high pressure fuel leak on the main engine;(4)

(b) severe vibration from the main engine;(3)

(c) high cooling water temperature alarm on generator engine.(3)

(a) Explain what is meant by the term Machinery Abstract.(4)

(b) List SIX items which would be recorded in a typical Machinery Abstract.(6)

- (a) With reference to ship construction, define a bulkhead.(2)

(b) State the functions of bulkheads.(8)

- Describe the functions of a watertight bulkhead. (10)

- State the purpose of infra red photography, explaining where it could be used as part of a condition monitoring programme.(10)

6.(a) State SIX advantages of controllabe pitch propellers.(6)

(b) State FOUR disadvantages of controllable pitch propellers.(4)

Describe the working principle of the four stroke cycle.

(10)

Study Notes MDE Unit 1 Q1 Quiz 1 MDE Unit 1 Q1 Quiz 2 MDE Unit 1 Q1 Quiz 3 MDE Unit 1 Q1 Quiz 4

(a) With reference to the combustion of fuel, explain EACH of the following terms:

(i) atomisation; (3)

(ii) penetration; (2)

(iii) compression ratio.(1)

(b) State the factors which influence the terms explained in part (a).(4)

Study Notes MDE Unit 1 Q2,3 Quiz Answer

(a) Sketch a cross section through a four stroke diesel engine piston, labelling the MAIN components.(6)

(b) Describe the transfer of gas force from piston crown through to the crankshaft.(4)

Study Notes Quiz Answer

(a) State THREE desirable properties of piston rings. (3)

(b) State the materials commonly used for piston rings.(2)

(c) Sketch THREE different types of piston ring ends.(3)

(d) Explain why piston ring end clearance is necessary.(2)

Study Notes MDE Unit 2 Q1 Quiz

(a) Show, using sketches, the THREE clearances necessary for efficient piston ring functioning.(3)

(b) Explain why piston rings are necessary.(2)

(c) Explain why the clearances sketched in part (a) are necessary.(5)

Study Notes MDE Unit 2 Q2 Quiz

With reference to diesel engines thermal and mechanical efficiency, describe where the losses may occur.

(10)

Study Notes MDE Unit 2 Q3 Quiz

With reference to a diesel engine chain driven camshaft:

(a) state the important checks that must be made during the drive inspection;(6)

(b) explain why the checks described in part (a) are necessary.(4)

Study Notes MDE Unit 3 Q1 Quiz

With reference to engine timing belts or chains:

(a) state the cause of loss of timing drive tension;(2)

(b) state how this will affect the engine;(6)

(c) explain how slight loss of tension can be corrected.(2)

Study Notes MDE Unit 3 Q2 Quiz

Study Notes MDE Unit 3 Q3 Quiz

(a) Sketch a four stroke timing diagram, showing the position of fuel valve, exhaust valve and inlet valve operation.(8)

(b) Explain the meaning of the term valve overlap, stating its purpose.(2)

Study Notes MDE Unit 3 Q4 Quiz

(a) Describe the procedure for setting tappet clearance on diesel engine inlet/exhaust valves.(6)

(b) Explain the importance of tappet clearances.(4)

Study Notes MDE Unit 3 Q5 Quiz

Study Notes MDE Unit 3 Q6 Quiz

(a) Describe the function of a main engine turbocharger.(5)

(b) Describe how the turbocharger is cooled.(2)

(c) Describe how the turbocharger is lubricated.(3)

(a) Explain why air coolers are fitted after main engine turbo chargers.(6)

(b) Explain the effects of undercooling the charge air on the engine. (4)

With reference to large medium speed diesel engine turbo chargers:

(a) explain why a thrust bearing is needed;(4)

(b) state where the thrust bearing is fitted;(2)

(c) describe how the thrust bearing is lubricated.(4)

With reference to main engine turbo chargers, explain the purpose of EACH of the following:

(a) the volute casing;(3)

(b) the diffuser;(4)

(c) the nozzle ring.(3)

With reference to diesel engine turbocharger construction, explain the purpose of EACH of the following:

(a) labyrinth glands;(3)

(b) diffuser;(3)

(c) inducer;(2)

(d) thrust bearing.(2)

With reference to large medium speed diesel engine turbo chargers:

(a) explain what is meant by the term pulse system;(6)

(b) explain the advantage the pulse system has over the constant pressure system.(4)

With reference to a turbocharged engine fitted with charge air cooler, It is noticed that boost pressure at the inlet manifold is reducing over a period of time:

(a) list FOUR possible causes; stating a simple and economical in service maintenance routine that would rectify EACH(8)

(b) state the effect reduced inlet pressure at full load will have on the engine.(2)

(a) Explain why the air outlet from the turbocharger should be cooled before entering the diesel engine cylinder.(4)

(b) Explain why the charge air cooler has fins attached to its tubes.(2)

(c) State possible reasons why the charge air coolers performance may be reduced.(4)

With reference to air coolers, explain the purpose of EACH of the following:

(a) zinc anodes;(3)

(b) vent cocks;(3)

(c) tube fins.(4)

With reference to poor turbocharger performance:

(a) state FOUR possible causes;(4)

(b) describe the possible indications.(6)

(a) Sketch a cross section through a resilient/flexible mounting for a diesel engine, labelling the MAIN components.(8)

(b) State the special consideration necessary with respect to the engine installation when using the type of mounting in part (a).(2)

(a) Describe the operation and purpose of a diesel engine fuel nozzle.(6)

(b) State the defects diesel engine fuel nozzles may encounter during service.(4)

Study Notes MDE Unit 5 Q1 Quiz

(a) Sketch a section through the nozzle of a fuel injector, labelling the MAIN components.(6)

(b) Explain what is meant by EACH of the following terms:

(i) atomisation;(2)

(ii) penetration.(2)

Study Notes MDE Unit 5 Q2 Quiz

With reference to four stroke engines, explain the effects of EACH of the following:

(a) advanced fuel injection;(3)

(b) retarded fuel injection:(4)

(c) low compression pressure.(3)

Study Notes MDE Unit 5 Q3 Quiz

With reference to Bosch or jerk type fuel injection pumps:

(a) describe how the delivered quantity of fuel oil may be controlled;(6)

(b) explain the purpose of the delivery valve.(4)

Study Notes MDE Unit 5 Q4 Quiz

With reference to scroll type fuel injection pumps:

(a) describe how the delivered quantity of fuel may be varied:(5)

(b) explain the purpose of the delivery valve:(3)

(c) describe how fuel oil is prevented from spraying out if the high pressure pipe fails in service.(2)

Study Notes MDE Unit 5 Q5 Quiz

(a) Sketch a scroll type fuel pump, labelling the main components.(6)

(b) Explain how the pump sketched in part (a) may vary the end of delivery.(4)

Study Notes MDE Unit 5 Q6 Quiz

Explain, with the aid of labelled sketches, how a scroll type fuel pump meters the fuel for high and low loads.(10)

Study Notes MDE Unit 5 Q7 Quiz

Describe FIVE defects which may occur with main engine fuel injectors.(10)

Study Notes MDE Unit 5 Q8 Quiz

With reference to diesel engine crankcases:

(a) explain why crankcases may have relief valves fitted;(3)

(b) outline the circumstances which may cause the relief valves to operate;(5)

(c) state a safety detection system which may be fitted.(2)

Study Notes MDE Unit 6 Q1 Quiz

(a) Outline the actions which must be taken, by the on-watch engineer when the engine crankcase oil mist detector activates.(5)

(b) Sketch a crankcase explosion relief door, labelling the MAIN components.(5)

Study Notes MDE Unit 6 Q2 Quiz

The daily engine log shows the engine crankcase pressure gauge is indicating a much higher value than the normal reading.

(a) State the implications of this and the immediate actions that should be taken.(2)

(b) Outline the checks and investigations that should be undertaken to ascertain the cause of this increased crankcase pressure.(8)

Study Notes MDE Unit 6 Q3 Quiz

(a) Sketch an overspeed trip of the centrifugal type. (6)

(b) Describe the operation of the overspeed trip sketched in part (a). (4)

Study Notes MDE Unit 7 Q1 Quiz

Describe FOUR safety cut outs/trips which may be fitted to a diesel engine, explaining how EACH functions. (10)

Study Notes MDE Unit 7 Q2 Quiz

Describe a procedure for manually testing the set points on diesel generator HT cooling water, high temperature alarm and shut down.

Study Notes Quiz

Describe a procedure for manually testing the set points on diesel generator HT cooling water, high temperature alarm and shut down.

(10)

Study Notes MDE Unit 7 Q4 Quiz

Describe a procedure for manually testing the set points on a diesel engine lubricating oil low pressure alarm and shut down using a pressure calibrator.(10)

Study Notes MDE Unit 7 Q5 Quiz

List TEN safety devices that may be fitted to a propulsion engine and gearbox arrangement, stating a reason why EACH device is fitted.

(10)

Study Notes MDE Unit 7 Q6 Quiz

Explain the meaning of EACH of the following diesel engine terms:

(a) overlap;(2)

(b) scavenging;(2)

(c) afterburning;(2)

(d) compression;(2)

(e) expansion.(2)

Study Notes MDE Unit 8 Q1 Quiz

Explain what is meant by EACH of the following terms:

(a) cetane number;(3)

(b) calorific value;(3)

(c) density;(2)

(d) viscosity.(2)

Study Notes MDE Unit 8 Q2 Quiz

With reference to tube type heat exchangers, explain the purpose of EACH of the following:

(a) baffle plates;(2)

(b) sliding tube plate;(2)

(c) tell tale ring;(2)

(d) vent cock;(2)

(e) anodes.(2)

Study Notes MDE Unit 8 Q3 Quiz

With reference to diesel engines, explain EACH of the following terms:

(a) top dead centre;(1)

(b) bottom dead centre;(1)

(c) piston stroke;(2)

(d) swept volume;(2)

(e) clearance volume;(2)

(f) compression ratio.(2)

Study Notes MDE Unit 8 Q4 Quiz

With reference to distillate fuel oil, explain EACH of the following:

(a) why it often needs treatment before the engine;(6)

(b) why it sometimes needs cooling after the engine.(4)

MDE Unit 9 Q1 MDE Unit 9 Q1 Quiz

(a) List FIVE products directly obtained from the distillation of Crude Oil, stating a typical use for EACH on board a vessel.(5)

(b) With reference to ISO 8217, aluminium & silicon oxides in fuel, state EACH of the following:

(i) how they get there;(2)

(ii) what effect they will have on engine performance;(2)

(iii) how they are removed from the fuel.(1)

MDE Unit 9 Q2 MDE Unit 9 Q2 Quiz

With reference to microbial infestation of distillate fuel:

(a) describe what is meant by the term microbe;(1)

(b) state what microbes need to survive;(2)

(c) describe the possible diesel engine problems;(5)

(d) describe how it can be identified.(2)

MDE Unit 9 Q3 MDE Unit 9 Q3 Quiz

With reference to diesel engine fuel:

(a) explain the meaning of the term microbial contamination;(1)

(b) describe the possible problems the engine may encounter if the fuel received is contaminated with microbes;(4)

(c) explain how microbial contamination can be avoided;(3)

(d) explain the actions to be taken if microbial contamination is severe.

(2)

MDE Unit 9 Q4 MDE Unit 9 Q4 Quiz

(a) Explain what is meant by the term flashpoint of bunker fuel stored on board.(1)

(b) Describe the importance of knowing the flash point of the bunker fuel stored on board.(1)

(c) Describe a method in common use for ascertaining the flashpoint of bunker fuel.(4)

(d) State the SOLAS requirements, with respect to temperature, for storage of bunker fuel in an engine room.(4)

MDE Unit 9 Q5 MDE Unit 9 Q5 Quiz

With reference to distillate fuel, explain the potential problem for EACH of the following, stating how they may be avoided:

(a) flash point;(3)

(b) wax;(3)

(c) microbes.(4)

MDE Unit 9 Q6 MDE Unit 9 Q6 Quiz

Describe the engine and system problems created by EACH of the following common contaminants in distillate fuel oil:

(a) water;(3)

(b) solids;(3)

(c) microbes.(4)

MDE Unit 9 Q7 MDE Unit 9 Q7 Quiz

(a) Describe how contamination of fuel oil by EACH of the following can occur:

(i) microbes;(2)

(ii) sodium.(2)

(b) Describe how to avoid fuel system and engine related problems with reference to the TWO contaminants in part (a).(6)

MDE Unit 9 Q8 MDE Unit 9 Q8 Quiz

(a) Explain what is meant by EACH of the following fuel terms:

(i) cloud point;(2)

(ii) compatibility.(2)

(b) Describe how to avoid fuel system and engine related problems with reference to the TWO terms in part (a)(6)

MDE Unit 9 Q9 MDE Unit 9 Q9 Quiz

Describe, with the aid of a sketch, a typical distillate fuel supply system for a diesel engine, including ALL the safety devices.(10)

MDE Unit 9 Q10 MDE Unit 9 Q10 Quiz

With reference to distillate fuel oil material safety datasheets, describe with examples the information that would be included for EACH of the following:

(a) hazards; (4)

(b) first aid;(3)

(c) fire fighting measures.(3)

MDE Unit 9 Q11 MDE Unit 9 Q11 Quiz

(a) Describe TWO methods of cylinder liner lubrication in medium speed diesel engines.(6)

(b) Describe the possible effects of EACH of the following:

(i) insufficient lubrication;(2)

(ii) excessive lubrication.(2)

MDE Unit 10 Q1 MDE Unit 10 Q1 Quiz

(a) State FOUR functions of lubricating oil.(4)

(b) Explain EACH of the following terms:

(i) hydrostatic lubrication;(2)

(ii) boundary lubrication.(2)

(c) State ONE advantage and ONE disadvantage of using grease as a lubricant in a plain bearing.(2)

MDE Unit 10 Q2 MDE Unit 10 Q2 Quiz

With reference to diesel engine lubricating oil:

(a) state the main functions;(6)

(b) list FOUR contaminants that may be identified from laboratory analysis of a lubricating oil sample, stating their effects on the engine.(4)

MDE Unit 10 Q3 MDE Unit 10 Q3 Quiz

Describe, with reasons, FIVE properties required of lubricating oil.

(10)

MDE Unit 10 Q4 MDE Unit 10 Q4 Quiz

With reference to a gearbox:

(a) explain why large quantities of lubricating oil are used;(2)

(b) state FOUR possible causes of excessive lubricating oil temperature when at normal operating speeds;(4)

(c) state how EACH cause stated in part (b) may be remedied.(4)

MDE Unit 10 Q5 MDE Unit 10 Q5 Quiz

With reference to diesel engine lubricating oil:

(a) explain how the oil may become contaminated during service;(5)

(b) describe how to keep the oil in a satisfactory condition.(5)

MDE Unit 10 Q6 MDE Unit 10 Q6 Quiz

(a) Explain what is meant by microbial degradation of a lubricating oil.(4)

(b) State FOUR indications that could be observed if a lubricating oil was suffering from microbial degradation.(4)

(c) Describe TWO actions that should be taken on detecting the early start of microbial degradation of the main engine lubricating oil.(2)

MDE Unit 10 Q7 MDE Unit 10 Q7 Quiz

Explain the principle of operation of EACH of the following types of lubricating oil filter:

(a) magnetic;(2)

(b) centrifugal;(2)

(c) coalescer;(3)

(d) plate edge (eg auto-klean).(3)

MDE Unit 11 Q1 MDE Unit 11 Q1 Quiz

Describe, with the aid of a sketch, a coalescer type distillate fuel oil filter.(10)

MDE Unit 11 Q2 MDE Unit 11 Q2 Quiz

Describe, with the aid of a sketch, the operation of a centrifugal type lubricating oil filter, labelling the MAIN components.(10)

MDE Unit 11 Q3 MDE Unit 11 Q3 Quiz

(a) Describe FOUR factors influencing centrifugal separator efficiency.(4)

(b) Explain how oil loss occurs in a separator, stating how this can be minimised.(4)

(c) State the factors determining the discharge frequency of an engine lubricating oil purifier.(2)

MDE Unit 11 Q4 MDE Unit 11 Q4 Quiz

(a) Explain how the lubricating oil of a diesel engine may become contaminated with water.(6)

(b) Outline the problems that water in an engine oil may cause.(4)

MDE Unit 11 Q5 MDE Unit 11 Q5 Quiz

Describe how large medium speed diesel engine lubricating oil is kept in optimum condition.(10)

MDE Unit 11 Q6 MDE Unit 11 Q6 Quiz

Describe how the lubricating oil of a large medium speed diesel engine may be assessed on board.(10)

MDE Unit 11 Q7 MDE Unit 11 Q7 Quiz

With reference to plate type heat exchangers:

(a) sketch the assembly, labelling the main components and indicating the direction of flow;(5)

(b) state the materials used for the plates and seals;(2)

(c) state the purpose of the plates being corrugated;(2)

(d) state the purpose of tell tales.(1)

MDE Unit 12 Q1 MDE Unit 12 Q1 Quiz

(a) Describe, with the aid of a sketch, the construction of a plate type heat exchanger.(7)

(b) State THREE advantages of the plate types, compared with the tube type heat exchanger.(3)

MDE Unit 12 Q2 MDE Unit 12 Q2 Quiz

With reference to tube type heat exchangers, explain the purpose of EACH of the following:

(a) baffle plates;(2)

(b) sliding tube plate;(2)

(c) tell tale ring;(2)

(d) vent cock;(2)

(e) anodes.(2)

MDE Unit 12 Q3 Quiz

(a) State FOUR conditions for the fresh water cooling system treatment program to be effective.(4)

(b) State the function of the inhibitor used in fresh water cooling treatment.(3)

(c) Explain the safety considerations needed when handling the inhibitors.(3)

MDE Unit 13 Q1 MDE Unit 13 Q1 Quiz

With reference to diesel engine cooling water:

(a) explain why the water requires treatment;(6)

(b) describe the type of treatment that should be used.(4)

MDE Unit 13 Q2 MDE Unit 13 Q2 Quiz

(a) Describe, with the aid of a sketch, a keel type cooling water system, labelling the MAIN components.(6)

(b) Explain the purpose of EACH of the following in the cooling system:

(i) header tanks;(3)

(ii) vent lines.(1)

MDE Unit 13 Q3 MDE Unit 13 Q3 Quiz

With reference to the main engine cooling water systems:

(a) explain the purpose of the header tank;(4)

(b) explain why both heaters and coolers may be fitted;(4)

(c) state, with reasons, the type of pumps used.(2)

MDE Unit 13 Q4 MDE Unit 13 Q4 Quiz

Sketch a typical diesel engine cooling water system, describing the purpose of EACH component.(10)

MDE Unit 13 Q5 MDE Unit 13 Q5 Quiz

With reference to diesel engine water coolers:

(a) describe how performance is measured;(5)

(b) describe the possible causes of the performance falling off.(5)

MDE Unit 13 Q6 MDE Unit 13 Q6 Quiz

Describe, with the aid of a sketch, the operation of a diesel engine hydraulic oil start system, labelling the MAIN components, including all interlocks.(10)

MDE Unit 14 Q1 MDE Unit 14 Q1 Quiz

(a) Explain, with the aid of a diagram, the operation of a solenoid operated, battery powered electric starting system for an internal combustion engine.(6)

(b) Explain the term pre-engaged starter.(4)

MDE Unit 14 Q2 MDE Unit 14 Q2 Quiz

With reference to the operation of an air starting system of a large medium speed marine diesel engine fitted with individual air starting valves:

(a) state the checks to be carried out if the engine will not start when initiating the start sequence;(6)

(b) list FOUR safety devices fitted to the air start system.(4)

MDE Unit 14 Q3 MDE Unit 14 Q3 Quiz

(a) List FOUR safety interlocks that may be fitted to a direct air start medium speed diesel engine to prevent inadvertent starting during maintenance.(4)

(b) Explain, with the aid of a diagram, the opening period of an air start valve on a four stroke diesel engine in relation to the crank angle, inlet and exhaust valves.(6)

MDE Unit 14 Q4 MDE Unit 14 Q4 Quiz

Describe the checks and maintenance required for a main engine starting system that uses an air motor.(10)

MDE Unit 14 Q5 MDE Unit 14 Q5 Quiz

Describe the procedure to be adopted prior to removing a diesel engine cylinder head, including safety precautions.(10)

MDE Unit 15 Q1 MDE Unit 15 Q1 Quiz

(a) State the safety precautions necessary before removing a four stroke diesel engine cylinder head.(4)

(b) Explain the procedure for removing a four stroke diesel engine cylinder head.(6)

MDE Unit 15 Q2 MDE Unit 15 Q2 Quiz

Describe the inspection of a diesel engine piston that has already been removed from the engine.(10)

MDE Unit 15 Q3 MDE Unit 15 Q3 Quiz

(a) Describe how to calibrate a diesel engine cylinder liner, already removed from the engine.(6)

(b) State the precautions that should be taken during initial startup when putting a new liner into service.(4)

MDE Unit 15 Q4 MDE Unit 15 Q4 Quiz

(a) Describe the inspection of a cylinder liner and piston assembly, when the piston has been removed from the engine. (6)

(b) State possible faults which may be found.(4)

MDE Unit 15 Q5 MDE Unit 15 Q5 Quiz

(a) Describe the procedure for renewing a bottom end bearing of a diesel engine.(8)

(b) Describe the precautions necessary on initial startup of the engine.(2)

MDE Unit 15 Q6 MDE Unit 15 Q6 Quiz

Describe the possible causes and remedies for EACH of the following diesel engine faults:

(a) low lubricating oil pressure;(3)

(b) overheating;(3)

(c) unstable speed.(4)

MDE Unit 16 Q1 MDE Unit 16 Q1 Quiz

With reference to diesel engine high bearing temperatures:

(a) describe the possible causes;(5)

(b) explain the procedure to be adopted if detected.(5)

MDE Unit 16 Q2 MDE Unit 16 Q2 Quiz

With reference to leaking cylinder air start valves:

(a) describe how this may be detected whilst the engine is running;(2)

(b) describe the procedure on discovery;(4)

(c) list FOUR possible causes.(4)

MDE Unit 16 Q3 MDE Unit 16 Q3 Quiz

With reference to abnormal turbocharger vibration:

(a) explain the possible causes whilst operating at a steady speed;(5)

(b) describe how the causes explained in part (a) may be minimised.(5)

The air start pipework on a diesel engine attached to the cylinder head is becoming extremely hot.

Explain EACH of the following:

(a) the probable cause;(3)

(b) the consequences of this situation and the immediate action to be taken;(4)

(c) how this problem can be minimised.(3)

(a) State TWO possible causes for EACH of the following exhaust emissions:

(i) black smoke;(2)

(ii) blue smoke;(2)

(iii) white smoke.(2)

(b) State ONE remedy for EACH of the emissions in part (a).(3)

(c) State how combustion defects may be diagnosed.(1)

Describe the possible causes of abnormal diesel engine noises during operation.(10)

MDE Unit 16 Q7 MDE Unit 16 Q7 Quiz

Describe possible reasons for variations in the oil level of a main engine sump.(10)

MDE Unit 16 Q8 MDE Unit 16 Q8,9 Quiz

(a) Describe possible reasons for fluctuations in the oil level of a main engine sump.(8)

(b) State how spurious sump level alarms can be avoided.(2)

MDE Unit 16 Q9 Quiz

Describe the preparation and checks on a main propulsion system prior to going to sea.(10)

MDE Unit 16 Q10 MDE Unit 16 Q10 Quiz

With reference to fluid couplings for the main propulsion shaft:

(a) explain the principle of operation;(5)

(b) state how the transmitted torque may be varied;(2)

(c) state THREE advantages.(3)

MDE Unit 17 Q1 MDE Unit 17 Q1 Quiz

With reference to fluid couplings, explain the effects of EACH of the following:

(a) increasing oil flow between impellors;(3)

(b) increased oil temperature;(4)

(c) angular misalignment.(3)

MDE Unit 17 Q2 MDE Unit 17 Q2 Quiz

Sketch a fluid coupling, suitable for connecting an engine to a gearbox, labelling the main components.(10)

MDE Unit 17 Q3 MDE Unit 17 Q3 Quiz

With reference to an engine connected to a gearbox via a friction clutch, explain EACH of the following:

(a) why vibration from the engine should be damped;(7)

(b) how vibration damping is achieved.(3)

MDE Unit 18 Q1 MDE Unit 18 Q1 Quiz

Sketch a hydraulically operated, multi-plate, friction clutch, labelling the main components.(10)

MDE Unit 18 Q2 MDE Unit 18 Q2 Quiz

With reference to friction clutches, state EACH of the following:

(a) THREE advantages of a wet clutch;(3)

(b) THREE disadvantages of a wet clutch;(3)

(c) ONE advantage of multiple plates;(1)

(d) THREE disadvantages of multiple plates.(3)

MDE Unit 18 Q3 Quiz

With reference to pneumatically operated friction clutches, explain the effects of EACH of the following:

(a) oil contamination of friction pads;(3)

(b) reduced air pressure;(2)

(c) distorted friction pads;(2)

(d) angular misalignment.(3)

MDE Unit 19 Q1 MDE Unit 19 Q1 Quiz

With reference to pneumatic clutches used for medium speed main propulsion purposes:

(a) describe the operating principle of the clutch;(5)

(b) explain how this clutch may be engaged in the event of failure of the control system; (3)

(c) state TWO interlocks necessary for clutch operation.(2)

MDE Unit 19 Q2 MDE Unit 19 Q2 Quiz

With reference to a reduction gearing and pneumatic clutch arrangement of a propulsion system:

(a) state FIVE protection devices fitted;(5)

(b) explain the need for EACH device stated in part (a).(5)

MDE Unit 19 Q3 MDE Unit 19 Q3 Quiz

Describe, with the aid of a sketch, the operation of a diesel engine propulsion system air operated radial tyre type clutch.(10)

MDE Unit 19 Q4 MDE Unit 19 Q4 Quiz

(a) Describe a gearbox inspection. (6)

(b) State, with reasons, TWO gear tooth faults. (4)

MDE Unit 20 Q1 MDE Unit 20 Q1 Quiz

With reference to main reduction gearing:

(a) explain why lubricating oil should be supplied before the gearing rotates:(4)

(b) state the condition monitoring techniques that may be employed to assess the condition of the gearing.(6)

MDE Unit 20 Q2 MDE Unit 20 Q2 Quiz

With reference to reduction gears, state the advantages and disadvantages of EACH of the following:

(a) helical teeth compared with spur teeth;(5)

(b) double helix compared to single helix.(5)

MDE Unit 20 Q3 MDE Unit 20 Q3 Quiz

With reference to reduction gearing, explain EACH of the following:

(a) the purpose of the magnetic filter in the lubricating oil system;(3)

(b) why the surface finish of the gear teeth is important;(4)

(c) why EP lubricating oil is preferred.(3)

MDE Unit 20 Q4 MDE Unit 20 Q4 Quiz

Describe, with the aid of a sketch, an epicyclic planetary reduction gear.

(10)

MDE Unit 20 Q5 Quiz

(a) State how gearbox oil may become contaminated with water.(1)

(b) Explain the effects of water contamination of gearbox oil.(5)

(c) Describe the actions to be taken should a gearbox become contaminated with water.(4)

MDE Unit 20 Q6 MDE Unit 20 Q6 Quiz

(a) Sketch a block diagram of a lubricating oil system suitable for use with a reduction gearing, including all the protective devices.(5)

(b) State the engineering purpose/function of EACH item in the system sketched in part(a).(5)

MDE Unit 20 Q7 MDE Unit 20 Q7 Quiz

Explain why main reduction gearing uses oil sprayers for lubrication rather than rely on a wet sump and the gearing picking up oil as it rotates.(10)

MDE Unit 20 Q8 MDE Unit 20 Q8 Quiz

(a) Explain the difference between in line and vee type engines.(2)

(b) State the advantages of vee type engines.(2)

(c) Sketch TWO vee engine bottom end arrangement types.(6)

MDE Unit 21 Q1 MDE Unit 21 Q1 Quiz

Describe the principle of operation of a simple hydraulic governor.(10)

MDE Unit 21 Q2 MDE Unit 21 Q2 Quiz

- With reference to the International Maritime Organisation (IMO):

(a) state the THREE main categories of IMO Conventions;(3)

(b) state how IMO Conventions are enforced;(2)

(c) state the aim of the IMO Member State Audit Scheme (IMSAS).(5)

- With reference to the International Maritime Organisation (IMO):

(a) state SEVEN of the main matters considered by the Maritime Safety Committee (MSC);(7)

(b) list THREE other main committees of the IMO.(3)

- With reference to the International Safety Management Code (I.S.M):

(a) state the purpose of having a designated person ashore (d.p.a.);(6)

(b) state the TWO certificates that are required to be carried on a vessel in order to demonstrate compliance with the code.(4)

CHIEF ENGINEER Unit 2 I.S.M Q1

- With reference to the International Safety Management Code (I.S.M.):

(a) state the THREE main objectives of the I.S.M. code;(6)

(b) describe the role of the designated person ashore (d.p.a.).(4)

CHIEF ENGINEER Unit 2 I.S.M Q2

- Describe the role of EACH of the following:

(a) the International Maritime Organisation;(4)

(b) the Maritime and Coastguard Agency:(3)

(c) the Marine Accident Investigation Branch.(3)

CHIEF ENGINEER Unit 2 I.S.M Q3

- With reference to the International Convention for the Safety of Life at Sea (SOLAS), state the requirements for the routine testing of steering gears:

(a) prior to sailing from port;(5)

(b) at three monthly intervals while the vessel is proceeding on passage.(5)

CHIEF ENGINEER Unit 3 SOLAS Q1

- With reference to the International Convention for the Safety of Life at Sea (SOLAS 1974, as amended) Chapter XI section 2 – the International Ship and Port Security Code:

(a) list the FIVE basic requirements for ships in order to comply with the code;(5)

(b) list the basic procedures that will be required to be put in place in order for the vessel to operate at security level one.(5)

CHIEF ENGINEER Unit 3 SOLAS Q2

- SOLAS requires regular testing of Emergency Sources of Electrical Power.

Describe the recommended routine testing procedure for the emergency generator, in accordance with Maritime & Coastguard Agency (MCA) guidance.(10)

CHIEF ENGINEER Unit 3 SOLAS Q3

- With reference to the MARPOL Convention Annex I – Shipboard Oil Pollution Emergency Plan (SOPEP):

(a) outline FOUR minimum requirements that should be included in the plan;(4)

(b) describe the actions that should be taken on discovering an accidental discharge of oil during bunkering.(6)

CHIEF ENGINEER Unit 4 MARPOL – Oil Q1

- With reference to the MARPOL Convention Annex I:

(a) list SIX circumstances under which an entry must be made in the Oil Record Book;(6)

(b) detail the specific entries that must be made in the Oil Record Book following a routine overboard discharge of machinery space bilge water.(4)

CHIEF ENGINEER Unit 4 MARPOL – Oil Q2

- With reference to MARPOL Annex V (Prevention of Pollution by Garbage from Ships):

(a) state which vessels require a Garbage Record Book (GRB);(1)

(b) state the FOUR operations which require an entry in the GRB;(4)

(c) list the FIVE pieces of specific information required to be entered when an operation stated in part (b) is carried out.(5)

CHIEF ENGINEER Unit 5 MARPOL – Garbage Q1

- With reference to the International MARPOL Convention 73/78 Annex V – Garbage handling:

(a) list SIX defined categories of garbage;(6)

(b) list FOUR garbage handling procedures that require an entry in the garbage record book.(4)

CHIEF ENGINEER Unit 5 MARPOL – Garbage Q2

- With reference to the Inernational MARPOL Convention Annex V pollution of the sea by garbage:

(a) list SIX special areas that apply to the disposal of garbage;(6)

(b) state the disposal restrictions that are placed on EACH of the following categories of garbage within the various special areas:

(i) operational waste;(1)

(ii) ground-up food waste.(3)

CHIEF ENGINEER Unit 5 MARPOL – Garbage Q3

- As required by the STCW Convention:

(a) state THREE actions that the Officer in charge of an Engineering Watch undertakes when assisting maintenance, repair or emergency activities;(6)

(b) state TWO circumstances under which the Officer in charge of the Engineering Watch shall notify the Chief Engineer Officer without delay.(4)

2.Outline the engineering watchkeeping requirements, as stated in the STCW Convention, under EACH of the following conditions:

(a) restricted visibility;(3)

(b) coastal or congested waters;(3)

(c) ship at anchor in open roadstead or similar at sea condition.(4)

- With reference to the STCW ’78 as amended, machinery space watchkeeping requirements, state EACH of the following:

(a) the purpose of standing orders,(3)

(b) FOUR examples of standing orders,(4)

(c) the circumstances under which it would be inappropriate for an officer in charge of an engineering watch to hand over responsibility to a relief watchkeeper.(3)

- The UMS monitoring and control system of a ship has recently started to give false alarms and incorrect data printouts.

(a) State, with reasons, the possible causes.(5)

(b) State, with reasons, the action that should be taken to ensure continued safe operation of the vessel.(5)

CHIEF ENGINEER Unit 7 Alarms Q1

3.(a) Explain, with the aid of a sketch, what is meant by the term Reserve Buoyancy, stating why it is important.(4)

(b) Explain what is meant by Free Surface Effect, stating how this can be minimised.(6)

CHIEF ENGINEER Unit 7 Alarms Q2

- Describe the procedure for using the local, emergency steering position, should the bridge control system become inoperative.

(10)

CHIEF ENGINEER Unit 7 Alarms Q3

- With reference to the International Load Line Convention (ILLC):

(a) define weathertight;(2)

(b) define watertight;(2)

(c) state what a surveyor would check when inspecting a weathertight door;(2)

(d) describe what Freeing Ports are, explaining why they are important.(4)

- With reference to the International Load Line Convention:

(a) sketch and label a typical load line marking for a vessel certificated to operate in all zones;(5)

(b) define statutory minimum freeboard.(2)

(c) explain why there are different load lines for fresh water and sea water.(3)

- With reference to the International Convention on Load Lines:

(a) list SIX different trading areas that are applied to the measurement of the freeboard of a vessel;(2)

(b) outline FOUR circumstances that would cause a vessel to infringe the Load Line regulations if it attempted to proceed to sea.(8)

- With reference to the International Convention on Load Lines:

(a) define the terms freeboard and freeboard deck;(5)

(b) list FIVE items that would be inspected by a surveyor before issuing or endorsing a load line certificate.(5)

- With reference to the regulations regarding watchkeeping procedures:

(a) state the off-duty time to which a watchkeeper is legally entitled:

(i) in any twenty-four hour period;(3)

(ii) accumulatively over the period of one week;(1)

(b) list SIX circumstances under which it may be necessary to increase the watchkeeping manning of the machinery spaces.(6)

- The Marine Accident Investigation Branch (M.A.I.B.) carries out investigations into casualties and accidents involving United Kingdom flagged vessels.

(a) List TWO responsibilities of the M.A.I.B.(2)

(b) State the Statutory requirements for reporting an accident.(4)

(c) List FOUR types of incident that are defined as reportable accidents.(4)

4.(a) List SIX items of information that should be conveyed to the relieving officer, prior to taking over the engineering watch at sea.(6)

(b) State FOUR criteria which should be taken into account when deciding on the composition of the engineering watch.(4)

- (a) State the main purposes of the International Labour Organisation (ILO).(4)

(b) List SIX areas where the MLC Convention applies to workers at sea.(6)

- The Code of Safe Working Practice for Merchant Seafarers states that Permits to Work must be obtained before certain tasks can be undertaken.

(a) List the conditions to be met before a Permit to Work is issued.(4)

(b) State FOUR points that would be listed as part of a Permit to Work for a typical task within the machinery spaces of a vessel.(4)

(c) State the time period over which a Permit to Work remains in force, outside of workshop areas.(2)

CHIEF ENGINEER Unit 10 Code of Safe Working Practice Q1

- With reference to the Code of Safe Working Practices for Merchant Seafarers guidance on dangerous (enclosed) spaces:

(a) list FOUR examples of a dangerous (enclosed) space;(4)

outline the requirements to be satisfied before entering a dangerous (enclosed) space.(6)

CHIEF ENGINEER Unit 10 Code of Safe Working Practice Q2

- The Code of Safe Working Practice for Merchant Seafarers states that a Permit to Work must be obtained before certain tasks can be undertaken

(a) State the purposes of a Permit to Work.(4)

(b) List SIX items that need to be included on a Permit to Work.(6)

CHIEF ENGINEER Unit 10 Code of Safe Working Practice Q3

- With reference to a vessel’s maintenance:

(a) list FOUR reasons why it is desirable for machinery to be covered by a planned maintenance system;(4)

(b) state FOUR reasons why unscheduled maintenance may need to be performed;(4)

(c) state ONE example of acceptable unscheduled maintenance.(2)

CHIEF ENGINEER Unit 11 Machinary Maintenance Q1

- With reference to the ongoing machinery maintenance of a vessel:

(a) state FOUR reasons why reliance on breakdown maintenance is generally considered unacceptable;(4)

(b) list THREE examples of condition monitoring, stating the benefits of using condition monitoring as part of a planned maintenance system.(6)

CHIEF ENGINEER Unit 11 Machinary Maintenance Q2

- With reference to a vessel having no previous record of machinery maintenance:

(a) describe how a new planned maintenance system could be set up;

(6)

(b) list FOUR reasons for keeping records of all maintenance.(4)

CHIEF ENGINEER Unit 11 Machinary Maintenance Q3

3.(a) State FOUR reasons why an Engine Room Log should be completed.(4)

(b) List SIX typical Engine Room Log entries.(6)

CHIEF ENGINEER Unit 11 Machinary Maintenance Q4

- With reference to Classification Society surveys, describe the purpose of EACH of the following:

(a) Annual Surveys;(3)

(b) Docking Surveys;(3)

(c) Special Surveys.(4)

CHIEF ENGINEER Unit 12 Classification Q1

- With reference to the classification of a vessel:

(a) describe how the continuous survey of machinery may be applied, stating the time interval over which the surveys take place;

(4)

(b) list SIX types of machinery that would be inspected during a continuous survey of machinery.(6)

CHIEF ENGINEER Unit 12 Classification Q2

- With reference to the classification of a vessel:

(a) list SIX items that would be inspected during a special hull survey;(3)

(b) describe how a continuous hull survey could be applied.(7)

CHIEF ENGINEER Unit 12 Classification Q3

- With reference to the classification survey of a vessel in dry dock:

(a) list EIGHT separate items of the hull and associated equipment that would be examined by the surveyor;(4)

(b) describe TWO ways in which the thickness of a steel hull may be determined.(6)

CHIEF ENGINEER Unit 12 Classification Q4

- (a) Define a Classification Society.(6)

(b) State the periods between docking surveys for a vessel less than 15 years old.(4)

CHIEF ENGINEER Unit 12 Classification Q5

- Explain the procedures carried out by a Classification Society for a new vessel to be built to class rules, and the class certificate being issued.(10)

CHIEF ENGINEER Unit 12 Classification Q6

7.(a) Describe what is meant by Continuous Class Machinery Surveys.

(4)

(b) State FOUR reasons why the fuel efficiency of a vessel maybe less than the build sea trials data.(4)

(c) List FOUR typical defects which may reduce the output of a centrifugal pump.(2)

CHIEF ENGINEER Unit 13 Surveys Q1

- With reference to vessel’s survey requirements:

(a) describe FIVE ways in which Government Surveyors will act in maintaining the statutory requirements of a vessel;(5)

(b) list FIVE ways in which Classification Surveyors can act to maintain the class and statutory requirements of the vessel.(5)

CHIEF ENGINEER Unit 13 Surveys Q2

- With reference to vessel’s survey requirements:

(a) state the possible consequences of either failing to obtain, or failing to renew a Statutory Certificate;(5)

(b) state what is meant by the Harmonisation system of survey and certification.(5)

CHIEF ENGINEER Unit 13 Surveys Q3

8.(a) Define the term harmonisation system of survey and certification.(4)

(b) With reference to a vessel of 500 gross tonnes or more and carrying 12 passengers, list SIX statutory certificates that are required to be carried out in order to demonstrate compliance with the IMO Conventions.(6)

CHIEF ENGINEER Unit 13 Surveys Q4

- With reference to plant monitoring as part of a planned maintenance system:

(a) list the various parts of a single main engine unit (piston, liner etc) that would be calibrated during full overhaul;(6)

(b) list the specific parts of the engine that would require examination, if a routine crankcase oil sample report indicated high levels of tin and lead.(4)

CHIEF ENGINEER Unit 14 Condition Monitoring Q1

- With reference to condition monitoring:

(a) explain how vibration analysis can be used as part of a planned maintenance system;(7)

(b) list SIX tests that can be carried out on crankcase oil in order to determine its suitability for further service.(3)

CHIEF ENGINEER Unit 14 Condition Monitoring Q2

6.(a) List SIX examples of condition monitoring that could be applied as part of a planned maintenance system.(6)

(b) Explain how condition monitoring can assist in expediting classification survey requirements.(4)

CHIEF ENGINEER Unit 14 Condition Monitoring Q3

- With reference to the periodical dry-docking of a vessel:

(a) state FIVE items of information that may be obtained from a docking plan;(5)

(b) state FIVE services that must be made available in order to maintain the safety of the vessel.(5)

CHIEF ENGINEER Unit 15 Periodical Dry Docking Q1

- With reference to the periodical dry-docking of a vessel:

(a) list SIX items of information that could be obtained from a docking plan;(6)

list FOUR conditions to be met prior to dry-docking a vessel.(4)

CHIEF ENGINEER Unit 15 Periodical Dry Docking Q2

- With reference to the periodical dry-docking of a vessel:

(a) list FIVE precautions that should be undertaken before the vessel enters the dock;(5)

(b) list FIVE inspections/precautions that should be undertaken before re-flooding the dock.(5)

CHIEF ENGINEER Unit 15 Periodical Dry Docking Q3

- With reference to the periodical routine dry-docking of a vessel:

(a) state FOUR reasons for dry-docking;

(b) outline THREE methods of testing a hull for watertight integrity.

CHIEF ENGINEER Unit 15 Periodical Dry Docking Q4

- With reference to dry-docking:

(a) state what is meant by the critical period on settling onto the dock blocks;(3)

(b) explain the reasons why this period is considered critical;(5)

(c) state how the danger is reduced.(2)

CHIEF ENGINEER Unit 16 Dry Docking Procedure Q1

8. (a) State the procedures and safety checks that should be undertaken prior to flooding a dry dock.(9)

(b) State who is responsible for signing the authority for a Flood Certificate.(1)

CHIEF ENGINEER Unit 16 Dry Docking Procedure Q2

8.(a) Describe the basic construction and operation of a Vertical Ship Lift.(6)

(b) List TWO advantages and TWO disadvantages of a Vertical Ship Lift.(4)

CHIEF ENGINEER Unit 16 Dry Docking Procedure Q3

- A vessel has bunkered 300 tonnes of diesel fuel. Given that the average combined sea power load of the vessel is 3000 kW and with a stated specific consumption of 0.35 kg/kWh, calculate EACH of the following:

(a) the daily fuel consumption of the vessel;(4)

(b) the safe steaming range of the vessel at a speed of 18 knots.(6)

CHIEF ENGINEER Unit 17 FUEL CONSUMPTION Q1

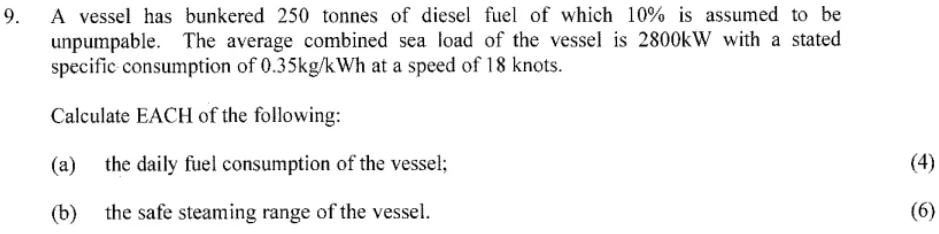

- A vessel has bunkered 250 tonnes of diesel fuel of which 10% is assumed to be unpumpable. The average combined sea load of the vessel is 2800kW with a stated specific consumption of 0.35kg/kWh at a speed of 18 knots.

Calculate EACH of the following:

(a) the daily fuel consumption of the vessel;(4)

(b) the safe steaming range of the vessel.(6)

CHIEF ENGINEER Unit 17 FUEL CONSUMPTION Q2

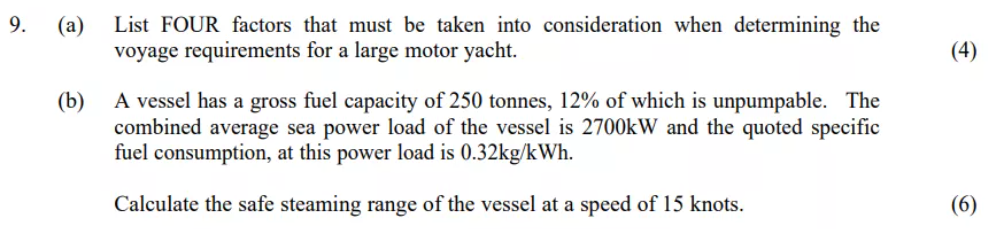

9.(a) List FOUR factors that must be taken into consideration when determining the voyage requirements for a large motor yacht.(4)

(b) A vessel has a gross fuel capacity of 250 tonnes, 12% of which is unpumpable. The combined average sea power load of the vessel is 2700kW and the quoted specific fuel consumption, at this power load is 0.32kg/kWh.

Calculate the safe steaming range of the vessel at a speed of 15 knots.(6)

CHIEF ENGINEER Unit 17 FUEL CONSUMPTION Q3

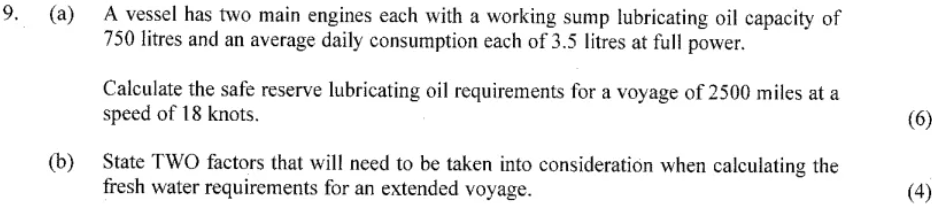

- (a) A vessel has two main engines each with a working sump lubricating oil capacity of 750 litres and an average daily consumption each of 3.5 litres at full power.

Calculate the safe reserve lubricating oil requirements for a voyage of 2500 miles at a speed of 18 knots.(6)

(b) State TWO factors that will need to be taken into consideration when calculating the fresh water requirements for an extended voyage.(4)

CHIEF ENGINEER Unit 17 FUEL CONSUMPTION Q4

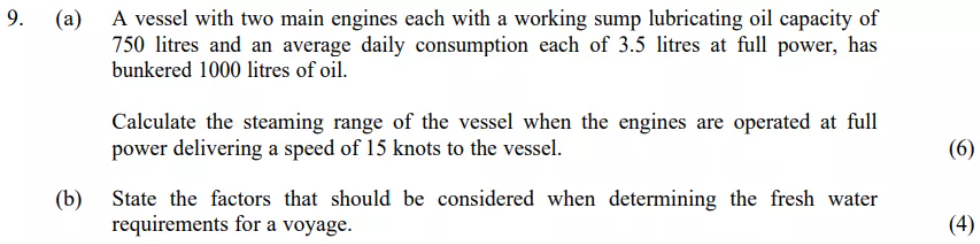

- (a) A vessel with two main engines each with a working sump lubricating oil capacity of 750 litres and an average daily consumption each of 3.5 litres at full power, has bunkered 1000 litres of oil.

Calculate the steaming range of the vessel when the engines are operated at full power delivering a speed of 15 knots to the vessel.(6)

(b) State the factors that should be considered when determining the fresh water requirements for a voyage.(4)

CHIEF ENGINEER Unit 17 FUEL CONSUMPTION Q5

- With reference to the use of a CO2 flooding system:

(a) list the precautions that should be taken before releasing CO2 into the machinery spaces of a vessel;(4)

(b) state the length of time that should be allowed to elapse before re-entry into the machinery spaces can be considered, following release of CO₂;(2)

(c) state the precautions that should be taken before the machinery space can be safely re-entered, following release of CO₂. (4)

CHIEF ENGINEER Unit 18 Fire Q1

- (a) List THREE types of fixed fire suppression installations commonly found on vessels.(3)

(b) Describe EACH method by which the THREE listed in part (a) extinguish fire.(4)

(c) State, with reasons, ONE advantage and ONE disadvantage of EACH.(3)

CHIEF ENGINEER Unit 18 Fire Q2

- (a) Write standing orders detailing the procedures to be followed in the event of a fire within the machinery spaces.(6)

(b) List FOUR types of portable fire extinguisher that could be found within the machinery spaces, stating on which class of fire EACH should be used.(4)

CHIEF ENGINEER Unit 18 Fire Q3

- Describe the methods by which a high pressure water-mist fire suppression system extinguishes fire, stating why it is more effective than a low pressure sprinkler system.(10)

CHIEF ENGINEER Unit 18 Fire Q4

- Describe, with the aid of sketches, the difference between an obscuration type smoke detector and a light scatter type smoke detector.(10)

CHIEF ENGINEER Unit 18 Fire Q5

4. (a) List FOUR aspects upon which a new person joining a vessel for the first time would receive instruction.(4)

(b) Detail SIX ways in which personal action can increase the risk of fire on a vessel.(6)

CHIEF ENGINEER Unit 18 Fire Q6

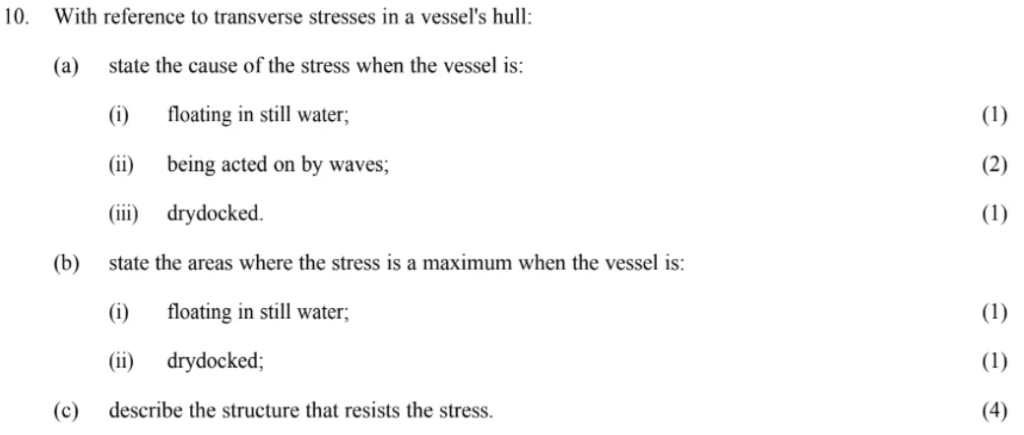

- With reference to transverse watertight bulkheads, state EACH of the following:

(a) FOUR reasons why these are an important part of the vessel’s structure;(4)

(b) the positions of each of the FOUR most important watertight bulkheads;(4)

(c) the reason why the foremost continuous bulkhead is of a stronger construction.(2)

CHIEF ENGINEER Unit 19 Bulkheads Q1

- With reference to watertight bulkheads:

(a) state FOUR reasons why these are an important part of the vessel’s structure;(4)

(b) state the precautions that are necessary to avoid accidents with power operated watertight doors.(6)

CHIEF ENGINEER Unit 19 Bulkheads Q2

- (a) Write standing orders detailing the procedures to be followed in the event of a severe flooding incident within the machinery spaces.(6)

(b) List the positions of the four main watertight bulkheads on a typical vessel.(4)

CHIEF ENGINEER Unit 19 Bulkheads Q3

5.(a) List FOUR examples of materials on board a vessel for which a Material Safety Data Sheet (MSDS) should be supplied.(4)

(b) List SIX items of information that could be obtained from a MSDS.(6)

CHIEF ENGINEER Unit 20 Misc Q1

Quick Closing Values -Remotely Operated

- With reference to remotely operated quick closing valves:

(a) state their purpose;(2)

(b) state where they would be fitted;(3)

(c) describe how they are tested.(5)

With reference to tank quick closing valves:

(a) describe, with the aid of sketches, TWO methods for remote actuation;(6)

(b) state where they would be fitted;(2)

(c) explain why they are fitted.(2)

2. Quiz. Study Notes.

With reference to quick closing valves:

(a) state where they would be fitted;(2)

(b) explain how they operate should a fire occur in EACH of the following:

the machinery space;(4)

(ii) close proximity to the valve.(4)

3. Quiz. Study Notes.

(a) State the purpose of fitting isolating valves in a ring fire main.(2)

(b) State the type of valve that should be fitted for isolating sections of a ring fire main.(2)