Quiz: AME Unit 10 Q2

Next Study Notes:AME Unit 10 Q3

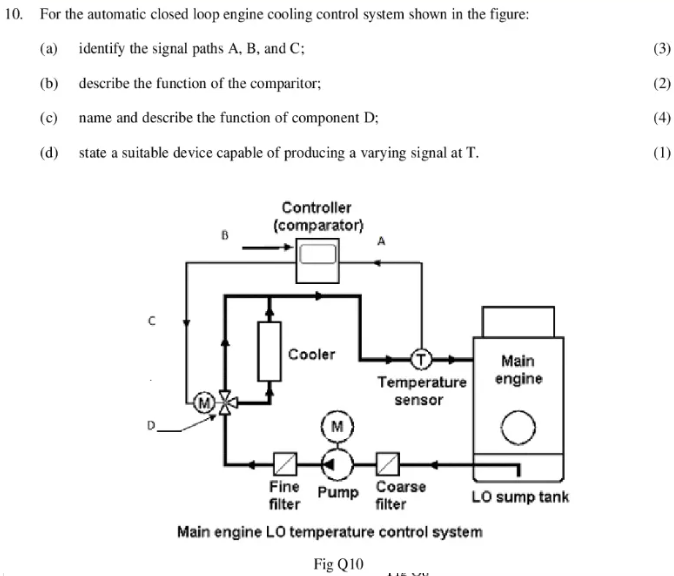

For the automatic closed loop engine cooling control system shown in the figure:

(a) identify the signal paths A, B, and C;(3)

(b) describe the function of the comparitor;(2)

(c) name and describe the function of component D;(4)

(d) state a suitable device capable of producing a varying signal at T.(1)

Closed Loop Engine Cooling Control System

A closed loop engine cooling control system is a system that automatically regulates engine coolant temperature by continuously monitoring and adjusting coolant flow based on engine operating conditions.

1. US4489680A – Engine temperature control system – Google Patents

How it works:

- Temperature Sensing: A temperature sensor measures the coolant temperature at a critical point (often the engine outlet).

- Controller: The engine control unit (ECU) or a dedicated controller receives the temperature signal.

- Comparison: The controller compares the measured temperature to a desired set point. 1. What Are The Differences Between Open Loop And Closed Loop Temperature Control? www.indmall.in

- Actuator Control: Based on the difference between the measured and desired temperatures, the controller adjusts the position of a coolant control valve (or other actuator) to regulate coolant flow.

- Feedback Loop: The system continuously monitors the coolant temperature, making adjustments as needed to maintain the desired temperature. 1. What is a closed loop temp control | Watlow www.watlow.com

Components:

- Temperature sensor: Measures coolant temperature. 1. Coolant Temperature – How it Works & How to Maintain It? – Uffizio www.uffizio.com

- Controller: Processes temperature data and controls actuators.

- Actuator: Controls coolant flow, such as a coolant control valve or pump speed.

- Coolant system: Includes the engine, radiator, water pump, and other components.

Benefits:

- Optimized engine performance: Maintains optimal engine operating temperature for maximum power and efficiency.

- Reduced engine wear: Protects engine components from overheating or excessive cooling.

- Improved fuel economy: Efficient temperature control can lead to better fuel consumption.

- Enhanced emissions: Proper engine temperature helps reduce harmful emissions.

Challenges:

- System complexity: Requires accurate sensors, reliable controllers, and efficient actuators.

- Sensor accuracy: Inaccurate temperature readings can lead to control issues.

- Controller tuning: Proper controller tuning is essential for optimal performance.

- Actuator response time: Slow actuator response can affect system stability.

Function of the Comparator in a Closed Loop Engine Cooling Control System

The comparator is the heart of a closed-loop control system. Its primary function is to compare the desired value (setpoint) of the engine coolant temperature with the actual measured value from the temperature sensor.

Key Role:

- Error Detection: The comparator continuously calculates the difference between the setpoint and the actual coolant temperature, generating an error signal.

- Control Signal Generation: This error signal is then sent to the controller, which determines the necessary adjustments to the cooling system (e.g., adjusting the coolant pump speed, opening or closing a thermostat).

In essence, the comparator acts as the decision-making unit that determines if corrective action is needed and provides the necessary information to the controller to initiate that action.

By constantly monitoring and comparing these values, the comparator ensures that the engine coolant temperature is maintained within the desired operating range.