Quiz: AME Unit 10 Q6

Next Study Notes:AME Unit 10 Q7

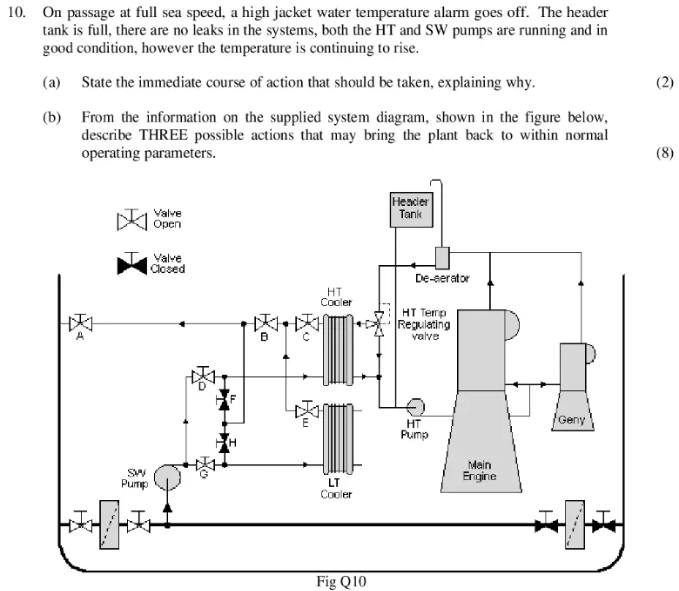

On passage at full sea speed, a high jacket water temperature alarm goes off. The header tank is full, there are no leaks in the systems, both the HT and SW pumps are running and in good condition, however the temperature is continuing to rise.

(a) State the immediate course of action that should be taken, explaining why.(2)

(b) From the information on the supplied system diagram, shown in the figure below, describe THREE possible actions that may bring the plant back to within normal operating parameters.(8)

Immediate Course of Action for High Jacket Water Temperature Alarm

Given the circumstances: high jacket water temperature, full header tank, no leaks, both pumps operating normally, and the temperature continuing to rise, the immediate course of action is to reduce engine load.

Explanation:

- Reducing engine load directly correlates to reduced heat generation by the engine. This is the quickest and most effective way to immediately decrease the rate at which the jacket water temperature is rising.

- Other systems are functioning normally: Given that the header tank is full, there are no leaks, and both pumps are operating correctly, it is unlikely that a system failure is the primary cause of the overheating.

- Time is critical: Allowing the temperature to continue rising can lead to severe engine damage, including warping of cylinder heads, piston seizures, or even engine failure.

Additional Actions:

While reducing engine load is the immediate priority, it’s crucial to investigate the underlying cause of the overheating once the situation is stabilized. Potential causes could include:

- Scale buildup: This can reduce the efficiency of the heat exchanger.

- Thermostat failure: A stuck closed thermostat can prevent proper coolant circulation.

- Cooling water pump inefficiency: Although both pumps are running, their performance might be compromised.

- Faulty temperature sensor: A malfunctioning sensor could provide inaccurate readings.

By following these steps, the risk of severe engine damage is mitigated, and the opportunity for a thorough investigation and repair is created.

HT and LT in Marine Engineering

HT stands for High Temperature.LT stands for Low Temperature.

These terms are commonly used in reference to the central cooling system on ships.

LT circuit is used for cooling other components like the lubricating oil cooler, charge air cooler, etc.

HT circuit typically refers to the engine jacket water cooling system.

Actions to Bring a Plant Back to Normal Operating Parameters

Disclaimer: The following actions are general in nature and may not be suitable for all plant types. Always consult specific operating procedures and safety guidelines for your particular plant.

Immediate Actions:

- Reduce load: This is typically the first step to reduce heat generation.

- Increase cooling water flow: If feasible, increasing the flow rate can enhance heat dissipation.

- Check for blockages or restrictions: Ensure there are no obstructions in the cooling water system.

- Monitor vital parameters: Continuously track temperature, pressure, and flow rates to identify any abnormal trends.

Corrective Actions:

Once the immediate crisis is averted, a more thorough investigation is required:

- Inspect heat exchangers: Check for fouling or scaling that reduces efficiency.

- Verify pump performance: Ensure cooling water pumps are operating at optimal capacity.

- Check thermostat function: Verify the thermostat is opening and closing correctly.

- Inspect cooling water system for leaks: Small leaks can reduce system efficiency.

- Analyze coolant condition: Check for contamination or degradation.

- Calibrate temperature sensors: Ensure accurate temperature readings.

Preventive Measures:

- Regular maintenance: Adhere to a preventive maintenance schedule for the cooling system.

- Water treatment: Implement water treatment programs to prevent scale and corrosion.

- Monitoring and alarms: Utilize advanced monitoring systems with appropriate alarm limits.

- Operator training: Ensure operators are well-trained in emergency procedures.

It’s essential to prioritize safety during any corrective action. Always follow established safety protocols and use appropriate personal protective equipment.

Bringing a Superyacht’s Cooling System Back to Normal Parameters

Understanding the Unique Challenges of Superyachts

Superyachts often have complex and high-performance cooling systems due to the demands of their propulsion systems, auxiliary equipment, and onboard amenities. This requires a tailored approach to troubleshooting and restoration.

Immediate Actions:

- Reduce engine load: As previously mentioned, this is the primary immediate action. On a superyacht, this might involve reducing speed, turning off auxiliary equipment, or even anchoring in a sheltered area.

- Increase seawater flow: If the cooling system relies on seawater, increasing its flow can help dissipate heat more effectively. This could involve adjusting sea chests or increasing pump speed (if possible).

- Isolate faulty components: If a specific component is suspected, isolating it can help pinpoint the problem. For instance, if a particular heat exchanger is suspected, bypassing it temporarily can provide insights.

Corrective Actions:

- Detailed inspection: A thorough inspection of the entire cooling system is essential. This includes checking for scale, fouling, or corrosion in heat exchangers, pumps, and piping.

- Thermostat function: Ensure the thermostat is operating correctly and not stuck in a closed position.

- Pump performance: Verify that cooling water pumps are delivering adequate flow and pressure.

- Seawater strainers: Check for blockages in seawater strainers, which can restrict flow.

- Antifreeze condition: Ensure the antifreeze/coolant mixture is correct and not contaminated.

- Temperature sensor calibration: Verify the accuracy of temperature sensors.

Preventive Measures:

- Regular maintenance: Implement a comprehensive maintenance schedule for the cooling system, including cleaning, inspections, and fluid analysis.

- Water quality monitoring: Regularly test the quality of seawater and freshwater used in the cooling system.

- Alarm systems: Ensure that temperature and pressure alarms are set at appropriate levels and are functioning correctly.

- Crew training: Provide regular training to crew members on emergency procedures and normal operating procedures.

Additional Considerations for Superyachts:

- Redundancy: Many superyachts have redundant cooling systems or components to enhance reliability. Utilize these systems if available.

- Specialized equipment: High-end diagnostic tools and equipment might be required for in-depth analysis.

- Expert assistance: Consider consulting with specialized marine engineers or cooling system experts for complex issues.

By following these guidelines and considering the unique characteristics of superyachts, you can effectively address high jacket water temperature issues and restore normal operating conditions.