Quiz: AME Unit 10 Q1

Next Study Notes:AME Unit 10 Q2

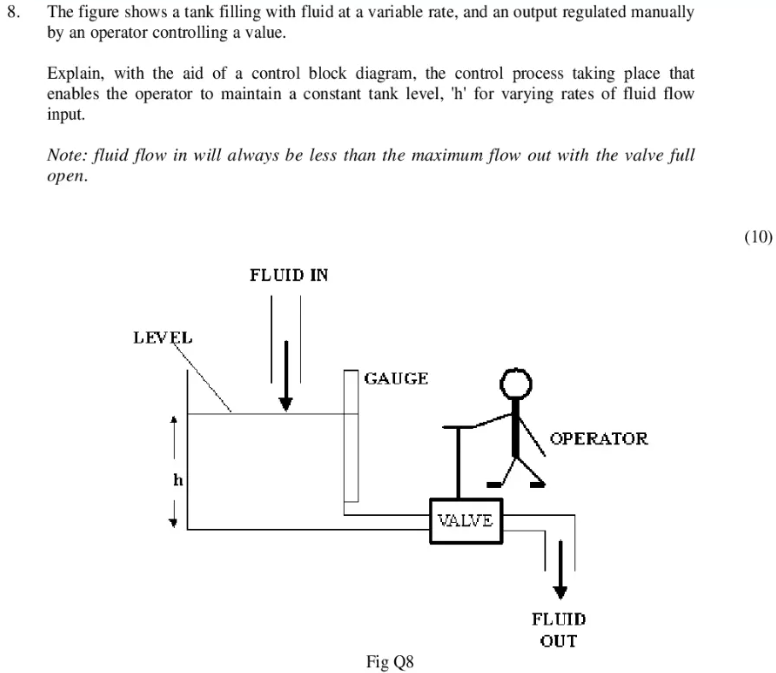

The figure shows a tank filling with fluid at a variable rate, and an output regulated manually by an operator controlling a value.

Explain, with the aid of a control block diagram, the control process taking place that enables the operator to maintain a constant tank level, ‘h’ for varying rates of fluid flow input.

Note: fluid flow in will always be less than the maximum flow out with the valve full open.

Manual Control of Tank Level

This is a classic example of a manual control loop.

Here’s a breakdown of the control process:

Components:

- Tank: Stores the fluid.

- Inlet: Where the fluid enters the tank at a variable rate.

- Outlet: Where the fluid exits the tank, controlled by a valve.

- Operator: The human element responsible for controlling the valve.

- Level Indicator: Provides information about the fluid level in the tank.

Control Process:

- Observation: The operator continuously observes the fluid level in the tank using the level indicator.

- Decision Making: Based on the observed level, the operator decides whether to increase, decrease, or maintain the valve opening.

- Action: The operator manually adjusts the valve accordingly.

- Effect: The adjustment of the valve affects the outflow rate, which in turn influences the fluid level in the tank.

- Feedback: The changed fluid level is observed, and the process repeats.

This is a closed-loop system, as the operator’s actions are based on the feedback from the system (the fluid level).

Challenges:

- Human Error: The operator’s decision-making and actions can be influenced by factors like fatigue, distraction, or lack of experience.

- Response Time: The operator’s reaction time can affect the system’s stability.

- Process Dynamics: Changes in the inlet flow rate or the tank’s geometry can make it difficult to maintain a constant level.

To improve the control performance, automation can be introduced using controllers and automatic valves.

Automated Control of Tank Level

Introducing Automation

To improve the accuracy, efficiency, and reliability of maintaining a constant tank level, we can implement an automated control system. This system replaces the human operator with a controller that continuously monitors the tank level and adjusts the valve accordingly.

Components of an Automated Control System:

- Tank: Stores the fluid.

- Inlet: Where the fluid enters the tank at a variable rate.

- Outlet: Where the fluid exits the tank, controlled by a valve.

- Level Sensor: Measures the fluid level in the tank and sends a signal to the controller.

- Controller: Receives the level signal, compares it to the setpoint (desired level), and calculates the required valve position.

- Actuator: Opens and closes the valve based on the controller’s signal.

Control Loop:

- Level Measurement: The level sensor measures the current fluid level in the tank.

- Error Calculation: The controller compares the measured level to the desired level (setpoint) and calculates the error.

- Control Signal Generation: Based on the error, the controller generates a control signal.

- Valve Adjustment: The actuator adjusts the valve position according to the control signal.

- Level Change: The adjusted valve position affects the outflow rate, which in turn changes the fluid level.

- Feedback: The process repeats as the level sensor continuously measures the fluid level.

Control Strategies:

- Proportional (P) Control: The controller output is proportional to the error.

- Integral (I) Control: The controller output is proportional to the integral of the error over time.

- Derivative (D) Control: The controller output is proportional to the rate of change of the error.

A combination of these control strategies (PID control) is often used to achieve optimal performance.

Benefits of Automated Control:

- Improved Accuracy: Maintains a more consistent tank level.

- Increased Efficiency: Optimizes valve operation.

- Reduced Labor Costs: Eliminates the need for constant human monitoring.

- Improved Response Time: Faster reaction to level changes.

Would you like to delve deeper into a specific control strategy or discuss potential challenges in implementing an automated system?

Opens in a new windowelectronicscoach.com

tank level control system