Vane Pump: Components and Operation

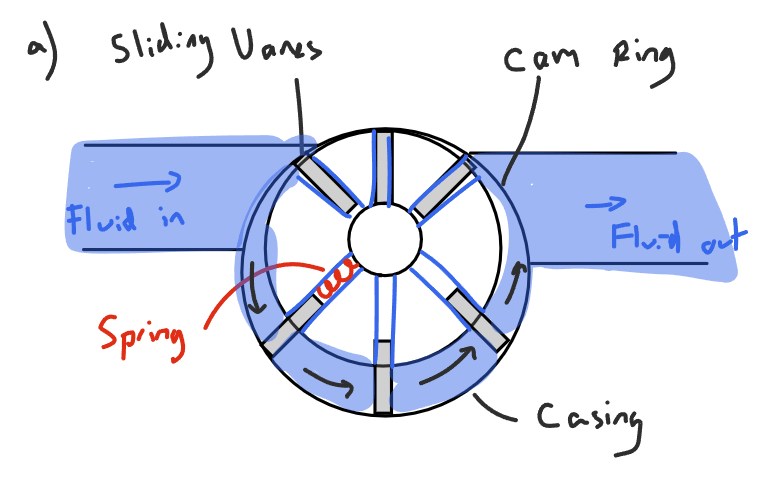

(a) Components of a Vane Pump:

A vane pump is a positive displacement pump that utilizes sliding vanes within a rotor to move fluid. Here’s a breakdown of its key components:

- Housing: The main body of the pump, typically made of cast iron or aluminum for strength and weight considerations.

- Rotor: A cylindrical or elliptical shaped rotor with slots machined along its circumference. The rotor is positioned eccentrically within the housing, meaning its center is not aligned with the center of the housing.

- Vanes: Flat, rectangular-shaped plates inserted into the slots of the rotor. The vanes are made from a wear-resistant material like spring steel or composite materials, and they slide freely within the slots. Spring mechanisms, centrifugal force, or a combination of both can be used to keep the vanes in contact with the housing wall.

- Cam Ring (Optional): In some vane pump designs, a circular inner lining within the housing surrounds the rotor. This cam ring provides a smooth surface for the vanes to slide against and can improve sealing efficiency.

- Inlet Port: The opening on the housing wall where fluid enters the pump chamber.

- Outlet Port: The opening on the housing wall where pressurized fluid exits the pump.

(b) Operation of a Vane Pump:

- Rotation: The rotor is driven by a shaft or motor, causing it to rotate eccentrically within the housing.

- Vane Movement: As the rotor rotates, the centrifugal force and/or spring mechanisms push the vanes outward, making them slide against the inner wall of the housing (or the cam ring, if present).

- Suction Creation: The eccentric positioning of the rotor creates increasing volume spaces between adjacent vanes on the inlet side of the pump. This decrease in volume generates a low-pressure zone at the inlet port, drawing fluid into the pump chamber.

- Trapping Fluid: The sliding vanes act as seals, trapping the fluid within the expanding chambers between them.

- Displacement and Pressure Build-Up: Continued rotation forces the trapped fluid around the outside of the rotor and towards the outlet port. The decreasing volume between the vanes and the housing progressively increases the pressure of the trapped fluid.

- Discharge: The high-pressure fluid is expelled from the pump through the outlet port.

Key Points:

- Positive Displacement: The fixed volume between the vanes and the housing ensures a constant amount of fluid is delivered with each rotation, regardless of the discharge pressure.

- Self-Priming: Vane pumps can be self-priming to a certain extent due to their ability to evacuate air from the inlet chamber.

- Variable Flow: Some vane pump designs allow for adjusting the angle of the vanes, enabling flow rate control.

This explanation provides a general overview of vane pump components and operation. Specific designs and functionalities may vary depending on the manufacturer and application.