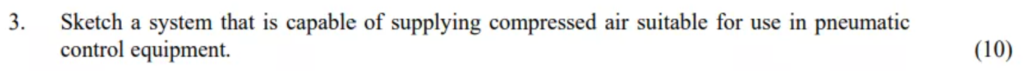

Sketch a system that is capable of supplying compressed air suitable for use in pneumatic control equipment.(10)

Compressed air system

Here’s a description of a compressed air system suitable for supplying pneumatic control equipment on a marine vessel:

System Components:

- Air Compressor:

- The heart of the system, responsible for compressing atmospheric air to the desired pressure. 1. Basic Components of Compressed Air Systems – jhfoster jhfoster.com

- Typically a rotary screw or reciprocating compressor, selected based on the required flow rate and pressure.

- Air Receiver (Storage Tank):

- Stores compressed air to provide a buffer and ensure a steady supply during peak demand or compressor downtime. 1. What is an Air Receiver? – Atlas Copco USA www.atlascopco.com

- Constructed from sturdy materials to withstand the system’s pressure.

- Equipped with safety features like a pressure gauge, safety relief valve, and drain valve. 1. Ship’s Service Air System – TSPS Engineering Manual – Massachusetts Maritime Academy weh.maritime.edu

- Air Dryer:

- Removes moisture from the compressed air to prevent condensation and corrosion in pneumatic components. 1. 10.10 Air dryers – SWEP www.swep.net

- Common types include refrigerated dryers and desiccant dryers.

- Filters:

- Remove particulate matter, oil, and other contaminants from the compressed air to protect the pneumatic equipment and ensure its longevity. 1. Control Air System – Marine Insight Academy academy.marineinsight.com

- Multiple stages of filtration may be used, from coarse pre-filters to fine coalescing filters.

- Pressure Regulator:

- Reduces the high pressure from the compressor/receiver to a suitable level for pneumatic control equipment, typically 6-8 bar.

- Maintains a constant pressure despite fluctuations in demand.

- Distribution Piping:

- Network of pipes that transport the compressed air from the receiver to various control equipment throughout the vessel.

- Made of corrosion-resistant materials like stainless steel or copper.

- Valves and Fittings:

- Control and regulate the flow of compressed air to different parts of the system. 1. Pneumatic Components: Types and Industrial Applications – Air Logic air-logic.com

- Include shut-off valves, control valves, check valves, and quick-release couplings.

- Pneumatic Control Equipment:

- The various devices that utilize the compressed air for control and automation, such as valves, actuators, cylinders, and other pneumatic tools.

System Operation:

- Air Compression: The air compressor draws in atmospheric air and compresses it to the required pressure. 1. Compressor | Airflow, Pressure & Efficiency – Britannica www.britannica.com

- Air Storage: The compressed air is stored in the air receiver, ready for use. 1. What is an Air Receiver? – Atlas Copco Greece www.atlascopco.com

- Air Treatment: The air passes through the air dryer and filters, removing moisture and contaminants.

- Pressure Regulation: The pressure regulator reduces the air pressure to the desired level for control equipment.

- Distribution: The clean, dry, and regulated compressed air is distributed through the piping network to various pneumatic control devices.

Key Considerations:

- Air Quality: Clean, dry air is essential for proper operation and longevity of pneumatic equipment. 1. The importance of dry compressed air systems for pneumatic tools tft-pneumatic.com

- Pressure Requirements: The system should be designed to deliver adequate pressure and flow rate to meet the demands of all connected control equipment.

- Safety: Pressure relief valves, safety interlocks, and regular inspections are vital to ensure safe operation.

- Maintenance: Regular maintenance of the compressor, dryer, filters, and other components is crucial to maintain air quality and system reliability.

By incorporating these key components and considerations, a compressed air system can effectively and reliably supply clean, dry, and regulated air suitable for operating pneumatic control equipment on a marine vessel, contributing to the vessel’s overall efficiency, safety, and automation.Sources and related content