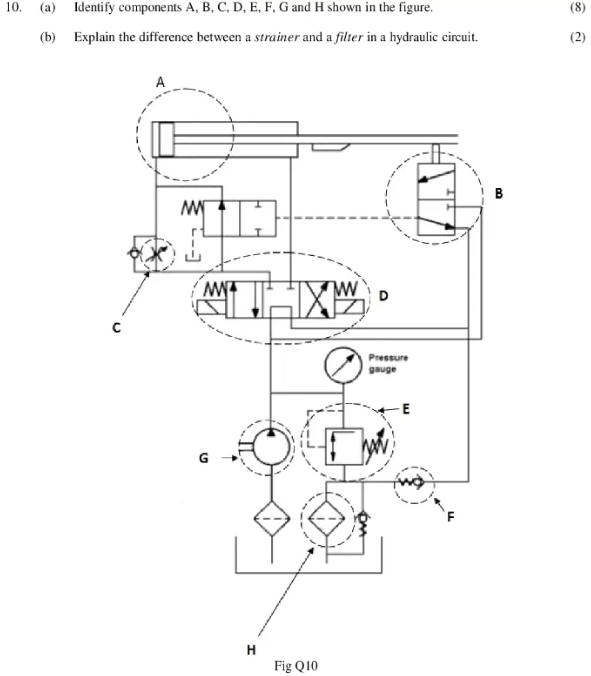

(a) Component Identification:

- A: Pressure gauge

- B: Hydraulic motor

- C: Relief valve

- D: Directional control valve

- E: Filter

- F: Reservoir

- G: Pump

- H: Strainer

(b) Strainer vs. Filter in Hydraulic Circuits:

While both strainers and filters remove contaminants from hydraulic fluid, they differ in their level of filtration and purpose:

Strainer:

- Function: Removes large particles like dirt, debris, and metal chips to protect pumps and other sensitive components from damage.

- Micron rating: Typically has a larger micron rating (50-200 microns), allowing smaller particles to pass through.

- Cleaning: Usually cleaned periodically by removing and emptying the collected debris.

Filter:

- Function: Removes finer particles and contaminants that could cause wear and tear on components.

- Micron rating: Has a smaller micron rating (10-25 microns) to capture smaller particles than strainers.

- Cleaning: May be replaceable or cleanable, depending on the type.

In essence, a strainer acts as the first line of defense against large debris, while a filter provides finer filtration for optimal system protection.

Remember, this information is based on the specific image you provided. The terminology and component functions may vary depending on the context and specific hydraulic system design.