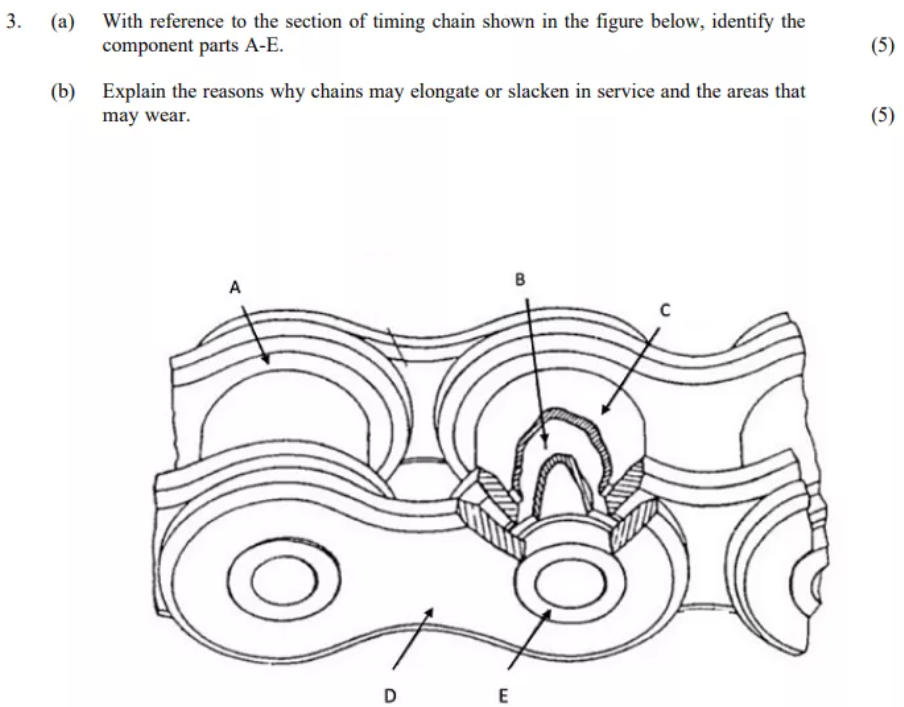

a) Here are the possible components

- Link Plate (Chain Body): The main body of the chain, consisting of alternating flat plates that connect the side plates. (Not labeled in the image)

- Inner Link Plate: The inner plate that connects the side plates on the inside of the chain. (Not labeled in the image)

- Outer Link Plate: The outer plate that connects the side plates on the outside of the chain. (Not labeled in the image)

- Side Plate: The side plates that fit between the link plates and form the chain’s sides. They interlock with the sprocket teeth. (Labeled in the image as A and C)

- Roller: A cylindrical roller between the side plates that reduces friction as the chain travels over the sprocket teeth. (Labeled in the image as B and D)

- Bush Pin: The pin that connects the side plates at each link. (Labeled in the image as E)

It’s important to note that the terminology may vary depending on the specific manufacturer or design.

b) There are several reasons why chains, including timing chains in diesel engines, may elongate or slacken in service:

1. Wear and Stretch:

- Metal Fatigue: Over time, the constant cyclical loading and unloading of the chain as it rotates causes metal fatigue. This weakens the metal in the chain links, causing them to elongate slightly.

- Roller and Bush Pin Wear: The rollers and bush pins that reduce friction between the chain and sprocket teeth wear down over time. This wear increases the space between links, effectively lengthening the chain.

2. Improper Tension:

- Incorrect Initial Tension: If the chain is not tensioned properly during installation, it can be too loose from the start. This allows for additional slack to develop as the chain wears.

- Tensioner Failure: The automatic tensioner maintains appropriate chain tension. A malfunctioning tensioner could allow the chain to become too loose.

Areas that may wear:

- Chain Links: As mentioned earlier, the link plates themselves experience metal fatigue and can elongate slightly.

- Rollers and Bush Pins: These components directly contact the sprocket teeth and are prone to wear. Worn rollers and bush pins increase the space between links, effectively lengthening the chain.

- Sprocket Teeth: While less common, the sprocket teeth can also wear down. This wear can cause the chain to ride higher on the teeth, which can contribute to chain slack.

- Chain Guides: Worn guides can allow the chain to move excessively, increasing wear on the chain and sprockets.

By understanding these reasons for chain elongation and the areas that wear, mechanics can perform regular inspections to identify potential problems early on. This allows for preventative maintenance such as chain and sprocket replacement before they wear excessively and cause engine performance issues or potential failure.

1970’s Tel-A-Train series Roller Chain And Silent Chain

https://www.youtube.com/watch?v=zlVBJKcQsMg