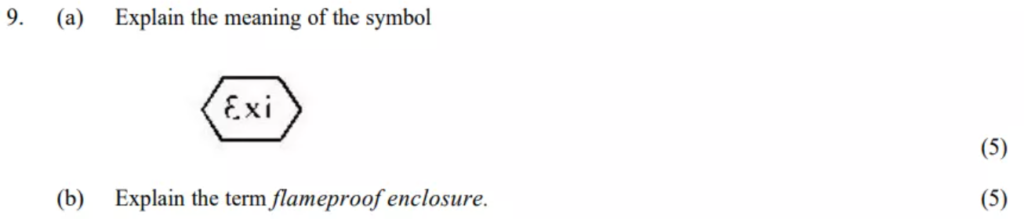

(a) Ex Symbol

The symbol you’re referring to most likely is the Ex symbol, used in marking electrical equipment for hazardous areas.

Here’s the breakdown:

- Ex: This prefix signifies that the equipment is designed for use in explosive atmospheres.

- Following Letters and Numbers: These letters and numbers provide specific information about the type of hazardous atmosphere the equipment is suitable for. Some examples include:

- Ex d: Suitable for flammable dust atmospheres.

- Ex ia: Suitable for explosive gas atmospheres caused by flammable gases or vapors.

- Numbers: Additional numbers might indicate the specific gas group (e.g., I, II, III) or temperature class (T1, T2, etc.) that the equipment is certified for.

For example, an Ex d IIB T4 marking indicates equipment suitable for use in zones with dust hazards caused by combustible materials (Zone 22) and with a maximum surface temperature not exceeding 135°C (T4).

As explained previously, the “Ex” prefix signifies the equipment is designed for explosive atmospheres, and the following letters and numbers provide specific details about the hazardous environment it can be used in.

In this specific case, the complete marking might be Ex II 2 G. Let’s break down the meaning of each part:

- Ex: Equipment for hazardous areas.

- II: Suitable for Zone 1 hazardous areas. Zone 1 areas are locations where flammable gas, vapor, or air mixtures are likely to be present continuously or for long periods.

- 2: Suitable for Group II hazardous substances. Group II includes flammable gases or vapors other than methane, such as propane, butane, or gasoline.

- G: Suitable for use in gaseous atmospheres.

Therefore, this particular equipment marked with Ex II 2 G is certified for use in Zone 1 hazardous areas where flammable gases or vapors other than methane (Group II) are present. It is crucial to ensure that the equipment you use in a hazardous area is appropriately rated for the specific zone and gas group based on the risk assessment of the environment.

(b) Flameproof Enclosure

A flameproof enclosure is a specially designed enclosure for electrical equipment that needs to operate in hazardous areas where flammable gases, vapors, or dusts are present. These enclosures are constructed to prevent internal sparks or ignition from escaping and igniting the surrounding atmosphere.

Here are some key features of flameproof enclosures:

- Strong Construction: They are typically made from robust materials like cast iron or steel to withstand an internal explosion without rupturing.

- Flame Paths: Seals and flame paths are carefully designed to prevent any flames or hot gases from escaping the enclosure. This might involve machined flanges with metal-to-metal contact surfaces or labyrinth seals.

- Breathers (Optional): Some enclosures might incorporate flameproof breathers that allow pressure equalization while preventing flames from entering.

- Ex Certification: Flameproof enclosures must be certified by a recognized testing agency to ensure they meet the relevant safety standards for use in hazardous areas.

By using flameproof enclosures, the risk of electrical equipment sparking and igniting a flammable atmosphere is significantly reduced, enhancing safety in hazardous environments.