4.(a) State THREE reasons for the operation of a High Pressure Cut-out in a vapour compression refrigeration system.(3)

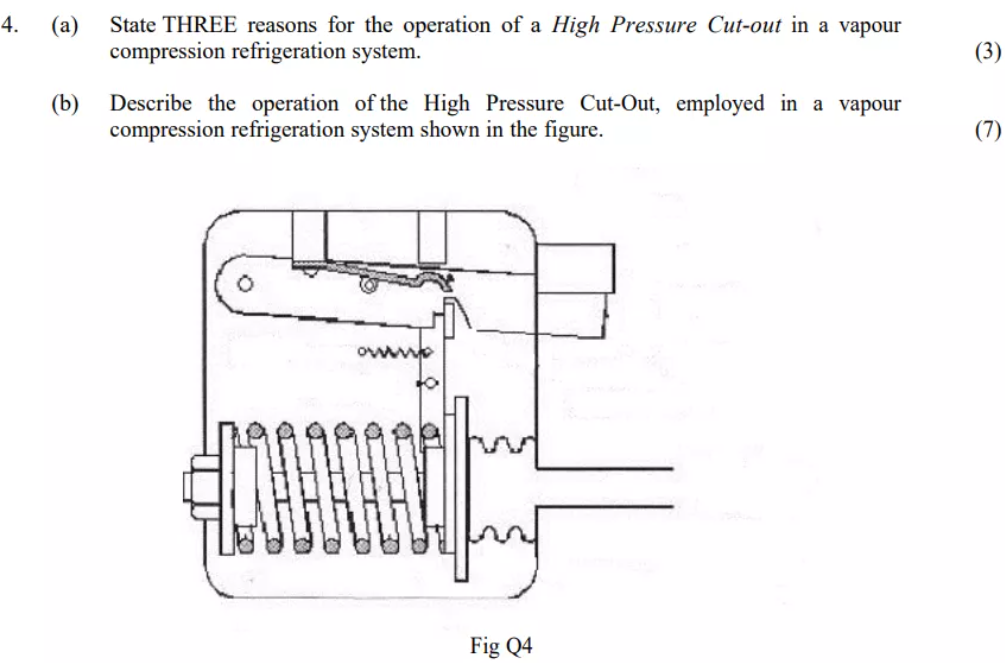

(b) Describe the operation of the High Pressure Cut-Out, employed in a vapour compression refrigeration system shown in the figure.

Reasons for the operation of a High Pressure Cut-out in a vapour compression refrigeration system

A high-pressure cut-out (HPCO) in a vapor compression refrigeration system is a safety device that shuts down the compressor if the discharge pressure rises above a predetermined safe limit. This automatic shutdown serves several crucial purposes:

- Compressor Protection:

- Preventing Mechanical Damage: Excessive pressure can put undue stress on the compressor’s internal components, leading to mechanical damage like broken valves, damaged pistons, or even seized bearings. The HPCO acts as a safeguard, preventing these costly and potentially dangerous failures.

- System Protection:

- Preventing Leaks and Ruptures: High pressure can also strain other components in the high-pressure side of the system, such as piping, hoses, and the condenser. The HPCO’s timely intervention helps avert leaks or ruptures that could release refrigerant and compromise system integrity.

- Avoiding Overheating: Excessive pressure can lead to abnormally high temperatures in the compressor and condenser, potentially causing overheating and damage to the system. The HPCO prevents this by shutting down the compressor before critical temperatures are reached.

- Personnel Safety:

- Preventing Explosive Ruptures: In extreme cases, uncontrolled high pressure can lead to catastrophic failures like explosive ruptures of components, posing a severe risk to personnel in the vicinity. The HPCO acts as a last line of defense against such dangerous situations.

Common Causes of High Pressure:

- Condenser Issues:

- Fouling or Blockage: Dirt, debris, or marine growth on the condenser tubes or fins can hinder heat transfer, causing refrigerant pressure to build up.

- Insufficient Cooling: If the condenser’s cooling medium (air or water) is not adequate or its flow is restricted, it can’t dissipate heat effectively, leading to high pressure.

- Fan Malfunction: In air-cooled condensers, a faulty fan can reduce airflow and cause overheating and high pressure.

- Refrigerant Overcharge:

- An excessive amount of refrigerant in the system increases the pressure, particularly in the high-pressure side.

- Non-Condensable Gases:

- The presence of air or other non-condensable gases in the system can increase the overall pressure and reduce the condenser’s efficiency, leading to high pressure.

- Expansion Valve Malfunction:

- A stuck closed or partially closed expansion valve restricts refrigerant flow, causing high pressure on the discharge side of the compressor.

Key Takeaway:

The high-pressure cut-out is a vital safety feature that protects the refrigeration system and personnel from the potential hazards of excessive pressure. By automatically shutting down the compressor when pressure limits are exceeded, it helps prevent damage, ensure system integrity, and promote a safe working environment.

Operation of a High Pressure Cut-Out

A High Pressure Cut-Out (HPCO) is a safety device in a refrigeration system designed to protect the compressor and other components from damage due to excessive high pressure.

Operation:

- Pressure Sensing: The HPCO is typically installed in the discharge line of the compressor, where it continuously monitors the refrigerant pressure. It may utilize a pressure sensing element like a diaphragm or a Bourdon tube.

- Threshold Setting: The HPCO has a preset pressure threshold, calibrated to a safe maximum pressure for the system.

- Trip Mechanism: When the pressure in the discharge line exceeds the preset threshold, the sensing element triggers a trip mechanism. This mechanism may be mechanical (e.g., a spring-loaded switch) or electrical (e.g., a pressure transducer sending a signal to a control circuit).

- Compressor Shutdown: The trip mechanism interrupts the electrical power supply to the compressor, causing it to shut down. This prevents further pressure buildup and potential damage to the system.

- Manual Reset: In most cases, the HPCO requires a manual reset once the underlying cause of the high pressure has been identified and corrected. This ensures that the operator is aware of the issue and takes necessary action before restarting the system.

Reasons for HPCO Activation:

- Condenser Issues:

- Fouling or blockage of condenser tubes/fins, hindering heat transfer.

- Insufficient cooling water flow or air circulation.

- Malfunctioning condenser fan.

- Refrigerant Overcharge: Excess refrigerant in the system increases pressure.

- Non-Condensable Gases: Presence of air or other gases in the system increases overall pressure.

- Expansion Valve Issues: A stuck closed or partially closed expansion valve restricts refrigerant flow, causing high discharge pressure.

- Other Causes: Compressor issues, blockage in the discharge line, or excessive ambient temperature can also trigger the HPCO.

Importance of HPCO:

- Protects the Compressor: Prevents mechanical damage to the compressor from excessive pressure.

- Safeguards the System: Protects other components like piping and the condenser from potential rupture.

- Enhances Safety: Prevents dangerous situations like explosive ruptures that could harm personnel.

Key Points:

- Regular Testing: It’s essential to periodically test the HPCO to ensure it’s functioning correctly at the set pressure threshold.

- Maintenance: Regular maintenance of the refrigeration system, including cleaning the condenser and checking refrigerant levels, helps prevent high-pressure conditions and unnecessary HPCO trips.

- Never Bypass: Bypassing the HPCO is extremely dangerous and can lead to severe consequences.

In essence, the high-pressure cut-out acts as a safety valve for the refrigeration system, protecting it from the damaging effects of over-pressurization and ensuring the safety of both equipment and personnel.

High Pressure Cutout

https://www.youtube.com/watch?v=6iPlKxcYJ8A