- With reference to the International Maritime Organisation (IMO):

(a) state the THREE main categories of IMO Conventions;(3)

(b) state how IMO Conventions are enforced;(2)

(c) state the aim of the IMO Member State Audit Scheme (IMSAS).(5)

- With reference to the International Maritime Organisation (IMO):

(a) state SEVEN of the main matters considered by the Maritime Safety Committee (MSC);(7)

(b) list THREE other main committees of the IMO.(3)

- With reference to the International Safety Management Code (I.S.M):

(a) state the purpose of having a designated person ashore (d.p.a.);(6)

(b) state the TWO certificates that are required to be carried on a vessel in order to demonstrate compliance with the code.(4)

CHIEF ENGINEER Unit 2 I.S.M Q1

- With reference to the International Safety Management Code (I.S.M.):

(a) state the THREE main objectives of the I.S.M. code;(6)

(b) describe the role of the designated person ashore (d.p.a.).(4)

CHIEF ENGINEER Unit 2 I.S.M Q2

- Describe the role of EACH of the following:

(a) the International Maritime Organisation;(4)

(b) the Maritime and Coastguard Agency:(3)

(c) the Marine Accident Investigation Branch.(3)

CHIEF ENGINEER Unit 2 I.S.M Q3

- With reference to the International Convention for the Safety of Life at Sea (SOLAS), state the requirements for the routine testing of steering gears:

(a) prior to sailing from port;(5)

(b) at three monthly intervals while the vessel is proceeding on passage.(5)

CHIEF ENGINEER Unit 3 SOLAS Q1

- With reference to the International Convention for the Safety of Life at Sea (SOLAS 1974, as amended) Chapter XI section 2 – the International Ship and Port Security Code:

(a) list the FIVE basic requirements for ships in order to comply with the code;(5)

(b) list the basic procedures that will be required to be put in place in order for the vessel to operate at security level one.(5)

CHIEF ENGINEER Unit 3 SOLAS Q2

- SOLAS requires regular testing of Emergency Sources of Electrical Power.

Describe the recommended routine testing procedure for the emergency generator, in accordance with Maritime & Coastguard Agency (MCA) guidance.(10)

CHIEF ENGINEER Unit 3 SOLAS Q3

- With reference to the MARPOL Convention Annex I – Shipboard Oil Pollution Emergency Plan (SOPEP):

(a) outline FOUR minimum requirements that should be included in the plan;(4)

(b) describe the actions that should be taken on discovering an accidental discharge of oil during bunkering.(6)

CHIEF ENGINEER Unit 4 MARPOL – Oil Q1

- With reference to the MARPOL Convention Annex I:

(a) list SIX circumstances under which an entry must be made in the Oil Record Book;(6)

(b) detail the specific entries that must be made in the Oil Record Book following a routine overboard discharge of machinery space bilge water.(4)

CHIEF ENGINEER Unit 4 MARPOL – Oil Q2

- With reference to MARPOL Annex V (Prevention of Pollution by Garbage from Ships):

(a) state which vessels require a Garbage Record Book (GRB);(1)

(b) state the FOUR operations which require an entry in the GRB;(4)

(c) list the FIVE pieces of specific information required to be entered when an operation stated in part (b) is carried out.(5)

CHIEF ENGINEER Unit 5 MARPOL – Garbage Q1

- With reference to the International MARPOL Convention 73/78 Annex V – Garbage handling:

(a) list SIX defined categories of garbage;(6)

(b) list FOUR garbage handling procedures that require an entry in the garbage record book.(4)

CHIEF ENGINEER Unit 5 MARPOL – Garbage Q2

- With reference to the Inernational MARPOL Convention Annex V pollution of the sea by garbage:

(a) list SIX special areas that apply to the disposal of garbage;(6)

(b) state the disposal restrictions that are placed on EACH of the following categories of garbage within the various special areas:

(i) operational waste;(1)

(ii) ground-up food waste.(3)

CHIEF ENGINEER Unit 5 MARPOL – Garbage Q3

- As required by the STCW Convention:

(a) state THREE actions that the Officer in charge of an Engineering Watch undertakes when assisting maintenance, repair or emergency activities;(6)

(b) state TWO circumstances under which the Officer in charge of the Engineering Watch shall notify the Chief Engineer Officer without delay.(4)

2.Outline the engineering watchkeeping requirements, as stated in the STCW Convention, under EACH of the following conditions:

(a) restricted visibility;(3)

(b) coastal or congested waters;(3)

(c) ship at anchor in open roadstead or similar at sea condition.(4)

- With reference to the STCW ’78 as amended, machinery space watchkeeping requirements, state EACH of the following:

(a) the purpose of standing orders,(3)

(b) FOUR examples of standing orders,(4)

(c) the circumstances under which it would be inappropriate for an officer in charge of an engineering watch to hand over responsibility to a relief watchkeeper.(3)

- The UMS monitoring and control system of a ship has recently started to give false alarms and incorrect data printouts.

(a) State, with reasons, the possible causes.(5)

(b) State, with reasons, the action that should be taken to ensure continued safe operation of the vessel.(5)

CHIEF ENGINEER Unit 7 Alarms Q1

3.(a) Explain, with the aid of a sketch, what is meant by the term Reserve Buoyancy, stating why it is important.(4)

(b) Explain what is meant by Free Surface Effect, stating how this can be minimised.(6)

CHIEF ENGINEER Unit 7 Alarms Q2

- Describe the procedure for using the local, emergency steering position, should the bridge control system become inoperative.

(10)

CHIEF ENGINEER Unit 7 Alarms Q3

- With reference to the International Load Line Convention (ILLC):

(a) define weathertight;(2)

(b) define watertight;(2)

(c) state what a surveyor would check when inspecting a weathertight door;(2)

(d) describe what Freeing Ports are, explaining why they are important.(4)

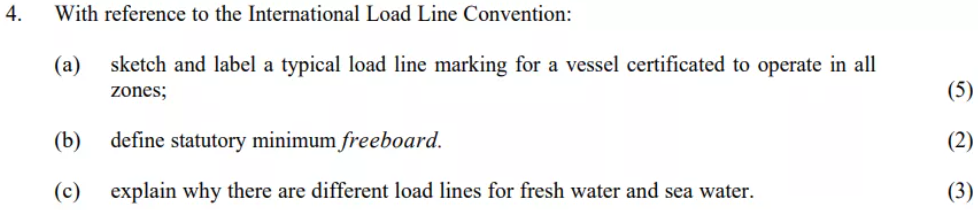

- With reference to the International Load Line Convention:

(a) sketch and label a typical load line marking for a vessel certificated to operate in all zones;(5)

(b) define statutory minimum freeboard.(2)

(c) explain why there are different load lines for fresh water and sea water.(3)

- With reference to the International Convention on Load Lines:

(a) list SIX different trading areas that are applied to the measurement of the freeboard of a vessel;(2)

(b) outline FOUR circumstances that would cause a vessel to infringe the Load Line regulations if it attempted to proceed to sea.(8)

- With reference to the International Convention on Load Lines:

(a) define the terms freeboard and freeboard deck;(5)

(b) list FIVE items that would be inspected by a surveyor before issuing or endorsing a load line certificate.(5)

- With reference to the regulations regarding watchkeeping procedures:

(a) state the off-duty time to which a watchkeeper is legally entitled:

(i) in any twenty-four hour period;(3)

(ii) accumulatively over the period of one week;(1)

(b) list SIX circumstances under which it may be necessary to increase the watchkeeping manning of the machinery spaces.(6)

- The Marine Accident Investigation Branch (M.A.I.B.) carries out investigations into casualties and accidents involving United Kingdom flagged vessels.

(a) List TWO responsibilities of the M.A.I.B.(2)

(b) State the Statutory requirements for reporting an accident.(4)

(c) List FOUR types of incident that are defined as reportable accidents.(4)

4.(a) List SIX items of information that should be conveyed to the relieving officer, prior to taking over the engineering watch at sea.(6)

(b) State FOUR criteria which should be taken into account when deciding on the composition of the engineering watch.(4)

- (a) State the main purposes of the International Labour Organisation (ILO).(4)

(b) List SIX areas where the MLC Convention applies to workers at sea.(6)

- The Code of Safe Working Practice for Merchant Seafarers states that Permits to Work must be obtained before certain tasks can be undertaken.

(a) List the conditions to be met before a Permit to Work is issued.(4)

(b) State FOUR points that would be listed as part of a Permit to Work for a typical task within the machinery spaces of a vessel.(4)

(c) State the time period over which a Permit to Work remains in force, outside of workshop areas.(2)

CHIEF ENGINEER Unit 10 Code of Safe Working Practice Q1

- With reference to the Code of Safe Working Practices for Merchant Seafarers guidance on dangerous (enclosed) spaces:

(a) list FOUR examples of a dangerous (enclosed) space;(4)

outline the requirements to be satisfied before entering a dangerous (enclosed) space.(6)

CHIEF ENGINEER Unit 10 Code of Safe Working Practice Q2

- The Code of Safe Working Practice for Merchant Seafarers states that a Permit to Work must be obtained before certain tasks can be undertaken

(a) State the purposes of a Permit to Work.(4)

(b) List SIX items that need to be included on a Permit to Work.(6)

CHIEF ENGINEER Unit 10 Code of Safe Working Practice Q3

- With reference to a vessel’s maintenance:

(a) list FOUR reasons why it is desirable for machinery to be covered by a planned maintenance system;(4)

(b) state FOUR reasons why unscheduled maintenance may need to be performed;(4)

(c) state ONE example of acceptable unscheduled maintenance.(2)

CHIEF ENGINEER Unit 11 Machinary Maintenance Q1

- With reference to the ongoing machinery maintenance of a vessel:

(a) state FOUR reasons why reliance on breakdown maintenance is generally considered unacceptable;(4)

(b) list THREE examples of condition monitoring, stating the benefits of using condition monitoring as part of a planned maintenance system.(6)

CHIEF ENGINEER Unit 11 Machinary Maintenance Q2

- With reference to a vessel having no previous record of machinery maintenance:

(a) describe how a new planned maintenance system could be set up;

(6)

(b) list FOUR reasons for keeping records of all maintenance.(4)

CHIEF ENGINEER Unit 11 Machinary Maintenance Q3

3.(a) State FOUR reasons why an Engine Room Log should be completed.(4)

(b) List SIX typical Engine Room Log entries.(6)

CHIEF ENGINEER Unit 11 Machinary Maintenance Q4

- With reference to Classification Society surveys, describe the purpose of EACH of the following:

(a) Annual Surveys;(3)

(b) Docking Surveys;(3)

(c) Special Surveys.(4)

CHIEF ENGINEER Unit 12 Classification Q1

- With reference to the classification of a vessel:

(a) describe how the continuous survey of machinery may be applied, stating the time interval over which the surveys take place;

(4)

(b) list SIX types of machinery that would be inspected during a continuous survey of machinery.(6)

CHIEF ENGINEER Unit 12 Classification Q2

- With reference to the classification of a vessel:

(a) list SIX items that would be inspected during a special hull survey;(3)

(b) describe how a continuous hull survey could be applied.(7)

CHIEF ENGINEER Unit 12 Classification Q3

- With reference to the classification survey of a vessel in dry dock:

(a) list EIGHT separate items of the hull and associated equipment that would be examined by the surveyor;(4)

(b) describe TWO ways in which the thickness of a steel hull may be determined.(6)

CHIEF ENGINEER Unit 12 Classification Q4

- (a) Define a Classification Society.(6)

(b) State the periods between docking surveys for a vessel less than 15 years old.(4)

CHIEF ENGINEER Unit 12 Classification Q5

- Explain the procedures carried out by a Classification Society for a new vessel to be built to class rules, and the class certificate being issued.(10)

CHIEF ENGINEER Unit 12 Classification Q6

7.(a) Describe what is meant by Continuous Class Machinery Surveys.

(4)

(b) State FOUR reasons why the fuel efficiency of a vessel maybe less than the build sea trials data.(4)

(c) List FOUR typical defects which may reduce the output of a centrifugal pump.(2)

CHIEF ENGINEER Unit 13 Surveys Q1

- With reference to vessel’s survey requirements:

(a) describe FIVE ways in which Government Surveyors will act in maintaining the statutory requirements of a vessel;(5)

(b) list FIVE ways in which Classification Surveyors can act to maintain the class and statutory requirements of the vessel.(5)

CHIEF ENGINEER Unit 13 Surveys Q2

- With reference to vessel’s survey requirements:

(a) state the possible consequences of either failing to obtain, or failing to renew a Statutory Certificate;(5)

(b) state what is meant by the Harmonisation system of survey and certification.(5)

CHIEF ENGINEER Unit 13 Surveys Q3

8.(a) Define the term harmonisation system of survey and certification.(4)

(b) With reference to a vessel of 500 gross tonnes or more and carrying 12 passengers, list SIX statutory certificates that are required to be carried out in order to demonstrate compliance with the IMO Conventions.(6)

CHIEF ENGINEER Unit 13 Surveys Q4

- With reference to plant monitoring as part of a planned maintenance system:

(a) list the various parts of a single main engine unit (piston, liner etc) that would be calibrated during full overhaul;(6)

(b) list the specific parts of the engine that would require examination, if a routine crankcase oil sample report indicated high levels of tin and lead.(4)

CHIEF ENGINEER Unit 14 Condition Monitoring Q1

- With reference to condition monitoring:

(a) explain how vibration analysis can be used as part of a planned maintenance system;(7)

(b) list SIX tests that can be carried out on crankcase oil in order to determine its suitability for further service.(3)

CHIEF ENGINEER Unit 14 Condition Monitoring Q2

6.(a) List SIX examples of condition monitoring that could be applied as part of a planned maintenance system.(6)

(b) Explain how condition monitoring can assist in expediting classification survey requirements.(4)

CHIEF ENGINEER Unit 14 Condition Monitoring Q3

- With reference to the periodical dry-docking of a vessel:

(a) state FIVE items of information that may be obtained from a docking plan;(5)

(b) state FIVE services that must be made available in order to maintain the safety of the vessel.(5)

CHIEF ENGINEER Unit 15 Periodical Dry Docking Q1

- With reference to the periodical dry-docking of a vessel:

(a) list SIX items of information that could be obtained from a docking plan;(6)

list FOUR conditions to be met prior to dry-docking a vessel.(4)

CHIEF ENGINEER Unit 15 Periodical Dry Docking Q2

- With reference to the periodical dry-docking of a vessel:

(a) list FIVE precautions that should be undertaken before the vessel enters the dock;(5)

(b) list FIVE inspections/precautions that should be undertaken before re-flooding the dock.(5)

CHIEF ENGINEER Unit 15 Periodical Dry Docking Q3

- With reference to the periodical routine dry-docking of a vessel:

(a) state FOUR reasons for dry-docking;

(b) outline THREE methods of testing a hull for watertight integrity.

CHIEF ENGINEER Unit 15 Periodical Dry Docking Q4

- With reference to dry-docking:

(a) state what is meant by the critical period on settling onto the dock blocks;(3)

(b) explain the reasons why this period is considered critical;(5)

(c) state how the danger is reduced.(2)

CHIEF ENGINEER Unit 16 Dry Docking Procedure Q1

8. (a) State the procedures and safety checks that should be undertaken prior to flooding a dry dock.(9)

(b) State who is responsible for signing the authority for a Flood Certificate.(1)

CHIEF ENGINEER Unit 16 Dry Docking Procedure Q2

8.(a) Describe the basic construction and operation of a Vertical Ship Lift.(6)

(b) List TWO advantages and TWO disadvantages of a Vertical Ship Lift.(4)

CHIEF ENGINEER Unit 16 Dry Docking Procedure Q3

- A vessel has bunkered 300 tonnes of diesel fuel. Given that the average combined sea power load of the vessel is 3000 kW and with a stated specific consumption of 0.35 kg/kWh, calculate EACH of the following:

(a) the daily fuel consumption of the vessel;(4)

(b) the safe steaming range of the vessel at a speed of 18 knots.(6)

CHIEF ENGINEER Unit 17 FUEL CONSUMPTION Q1

- A vessel has bunkered 250 tonnes of diesel fuel of which 10% is assumed to be unpumpable. The average combined sea load of the vessel is 2800kW with a stated specific consumption of 0.35kg/kWh at a speed of 18 knots.

Calculate EACH of the following:

(a) the daily fuel consumption of the vessel;(4)

(b) the safe steaming range of the vessel.(6)

CHIEF ENGINEER Unit 17 FUEL CONSUMPTION Q2

9.(a) List FOUR factors that must be taken into consideration when determining the voyage requirements for a large motor yacht.(4)

(b) A vessel has a gross fuel capacity of 250 tonnes, 12% of which is unpumpable. The combined average sea power load of the vessel is 2700kW and the quoted specific fuel consumption, at this power load is 0.32kg/kWh.

Calculate the safe steaming range of the vessel at a speed of 15 knots.(6)

CHIEF ENGINEER Unit 17 FUEL CONSUMPTION Q3

- (a) A vessel has two main engines each with a working sump lubricating oil capacity of 750 litres and an average daily consumption each of 3.5 litres at full power.

Calculate the safe reserve lubricating oil requirements for a voyage of 2500 miles at a speed of 18 knots.(6)

(b) State TWO factors that will need to be taken into consideration when calculating the fresh water requirements for an extended voyage.(4)

CHIEF ENGINEER Unit 17 FUEL CONSUMPTION Q4

- (a) A vessel with two main engines each with a working sump lubricating oil capacity of 750 litres and an average daily consumption each of 3.5 litres at full power, has bunkered 1000 litres of oil.

Calculate the steaming range of the vessel when the engines are operated at full power delivering a speed of 15 knots to the vessel.(6)

(b) State the factors that should be considered when determining the fresh water requirements for a voyage.(4)

CHIEF ENGINEER Unit 17 FUEL CONSUMPTION Q5

- With reference to the use of a CO2 flooding system:

(a) list the precautions that should be taken before releasing CO2 into the machinery spaces of a vessel;(4)

(b) state the length of time that should be allowed to elapse before re-entry into the machinery spaces can be considered, following release of CO₂;(2)

(c) state the precautions that should be taken before the machinery space can be safely re-entered, following release of CO₂. (4)

CHIEF ENGINEER Unit 18 Fire Q1

- (a) List THREE types of fixed fire suppression installations commonly found on vessels.(3)

(b) Describe EACH method by which the THREE listed in part (a) extinguish fire.(4)

(c) State, with reasons, ONE advantage and ONE disadvantage of EACH.(3)

CHIEF ENGINEER Unit 18 Fire Q2

- (a) Write standing orders detailing the procedures to be followed in the event of a fire within the machinery spaces.(6)

(b) List FOUR types of portable fire extinguisher that could be found within the machinery spaces, stating on which class of fire EACH should be used.(4)

CHIEF ENGINEER Unit 18 Fire Q3

- Describe the methods by which a high pressure water-mist fire suppression system extinguishes fire, stating why it is more effective than a low pressure sprinkler system.(10)

CHIEF ENGINEER Unit 18 Fire Q4

- Describe, with the aid of sketches, the difference between an obscuration type smoke detector and a light scatter type smoke detector.(10)

CHIEF ENGINEER Unit 18 Fire Q5

4. (a) List FOUR aspects upon which a new person joining a vessel for the first time would receive instruction.(4)

(b) Detail SIX ways in which personal action can increase the risk of fire on a vessel.(6)

CHIEF ENGINEER Unit 18 Fire Q6

- With reference to transverse watertight bulkheads, state EACH of the following:

(a) FOUR reasons why these are an important part of the vessel’s structure;(4)

(b) the positions of each of the FOUR most important watertight bulkheads;(4)

(c) the reason why the foremost continuous bulkhead is of a stronger construction.(2)

CHIEF ENGINEER Unit 19 Bulkheads Q1

- With reference to watertight bulkheads:

(a) state FOUR reasons why these are an important part of the vessel’s structure;(4)

(b) state the precautions that are necessary to avoid accidents with power operated watertight doors.(6)

CHIEF ENGINEER Unit 19 Bulkheads Q2

- (a) Write standing orders detailing the procedures to be followed in the event of a severe flooding incident within the machinery spaces.(6)

(b) List the positions of the four main watertight bulkheads on a typical vessel.(4)

CHIEF ENGINEER Unit 19 Bulkheads Q3

5.(a) List FOUR examples of materials on board a vessel for which a Material Safety Data Sheet (MSDS) should be supplied.(4)

(b) List SIX items of information that could be obtained from a MSDS.(6)