With reference to risk assessment and the Code of Safe Working Practices for Merchant Seamen:

(a) explain the purpose of a risk assessment;(4)

(b) state the person responsible for carrying out the risk assessment;(3)

(c) outline what should be considered when carrying out a risk assessment.(3)

With reference to the Code of Safe Working Practices for Merchant Seafarers and entering enclosed or confined spaces, state EACH of the following:

(a) the reasons why the atmosphere of any enclosed space is potentially dangerous;(4)

(b) the precautions to be taken before a potentially dangerous space is entered.(6)

- Outline the FOUR duties of workers as laid down in the Code of Safe Working Practices for Merchant Seamen.

(10)

- With reference to dangerous (enclosed) spaces onboard a vessel:

(a) state FOUR different examples;

(b) explain why the atmosphere may be dangerous.

10

(4)

(6)

- Outline the procedures and arrangements to be put into place before a permit to work is issued for entry into a confined space.

(10)

With reference to the International Safety Management code, describe EACH of the following:

(a) the Safety Management System (SMS);(5)

the role of the Designated Person (DP).

Quiz Hotel Service Unit 2 Safety Q1

Explain EACH of the following:

(a) Merchant Shipping Notices;(4)

(b) Marine Guidance Notes;(3)

(c) Marine Information Notes.(3)

Quiz Hotel Service Unit 2 Safety Q2

- With reference to the SOLAS requirements for conducting regular emergency musters and drills:

(a) state the accepted emergency signal for calling crew and passengers to lifeboat muster stations;(2)

(b) state when emergency drills must be carried out;(4)

(c) list FOUR types of emergency drill that must be conducted on a regular basis.(4)

Quiz Hotel Service Unit 2 Safety Q3

- With reference to noise levels in ships:

(a) describe the recommended maximum periods of time for personnel employed on watchkeeping duties within enclosed machinery spaces;(6)

(b) explain why these recommendations have been made;(2)

(c) state the permitted noise level at which hearing protection is:

recommended;(1)

(ii) mandatory.(1)

Quiz Hotel Service Unit 2 Safety Q4

9.List FIVE safety devices that may be fitted to the main swichboard of a vessel, stating reasons for fitting each device.

(10)

Quiz Hotel Service Unit 2 Safety Q5

- (a) State, with reasons, where the watch should be handed over on a vessel fitted with a UMS system, where the period of duty is 24 hours.(2)

(b) Outline the responsibility of the duty engineer with respect to EACH of the following:

(i) the Systems Status Board;(3)

(ii) the Oil Record Book;(3)

(iii) the main and auxiliary Machinery Maintenance Record Book.(2)

- With reference to unmanned machinery spaces:

(a) explain why machinery spaces should be visited on a regular basis;(2)

(b) explain how the human senses are used to monitor conditions in a machinery space;(4)

(c) outline the procedure to be adopted if a person wishes to enter a machinery space outside normal working hours.(4)

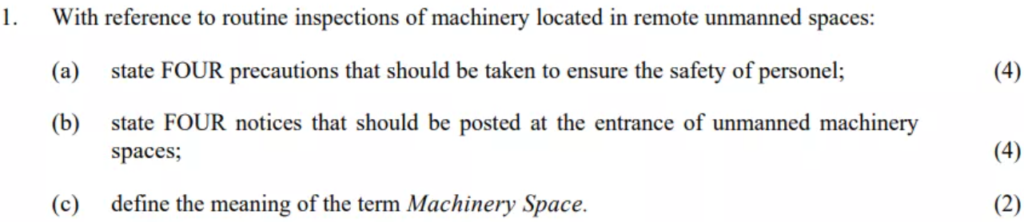

- With reference to routine inspections of machinery located in remote unmanned spaces:

(a) state FOUR precautions that should be taken to ensure the safety of personel;(4)

(b) state FOUR notices that should be posted at the entrance of unmanned machinery spaces;(4)

(c) define the meaning of the term Machinery Space.(2)

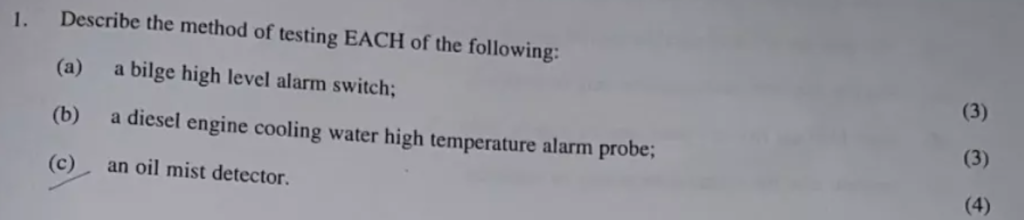

- Describe the method of testing EACH of the following:

(a) a bilge high level alarm switch;(3)

(b) a diesel engine cooling water high temperature alarm probe;(3)

(c) an oil mist detector.(4)

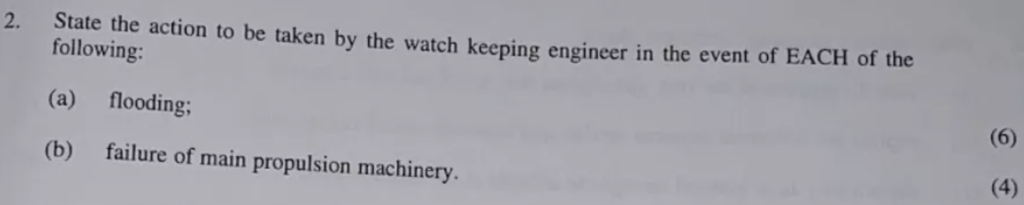

State the action to be taken by the watch keeping engineer in the event of EACH of the following:

(a) flooding;(6)

(b) failure of main propulsion machinery. (4)

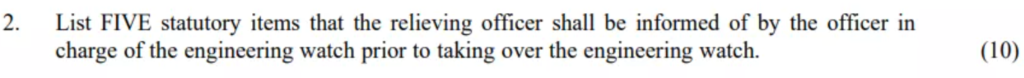

List FIVE statutory items that the relieving officer shall be informed of by the officer in charge of the engineering watch prior to taking over the engineering watch. (10)

- Describe the responsibilities of the off-going duty engineer with respect to EACH of the following:

(a) fuel service tanks;(2)

(b) oily water separator;(2)

(c) potable water tanks;(2)

(d) machinery space defect book;(2)

(e) main engine sump level.(2)

- With reference to the engine log books, explain the reasons for recording EACH of the following:

(a) running hours;(2)

(b) lubricating oil consumption;(2)

(c) fuel consumption;(2)

(d) salanity or chloride content of the engine jacket cooling water;(2)

(e) water content of lubricating oil.(2)

- With reference to the engine room log book:

(a) state THREE reasons for keeping such a log book;(6)

(b) state EACH of the following:

(i) the person responsible for its compilation;(1)

(ii) the interval at which it should be written up and signed;(1)

(iii) the procedure to be followed if a correction of entry is required;

(1)

(iv) the purpose of recording a general abstract for main and auxiliary engines.(1)

2.

(a) State THREE reasons for keeping a log.(6)

(b) State the person responsible for compiling the log.(1)

(c) State when the log should be compiled and signed.(1)

(d) Describe the action to be taken should a mistake be made during writing up the log.(2)

- With reference to the engine log books, explain the reasons for recording EACH of the following, and the effect on the engine should the temperatures be outside the normal parameters:

(a) exhaust temperatures;(3)

(b) cooling water inlet/outlet temperature;(3)

(c) lubricating oil temperature.(4)

- With reference to the engine log books, explain the reasons for recording EACH of the following, stating a possible cause should the readings be outside the normal parameters:

(a) LO Sump level;(4)

(b) cooling water inlet temperature;(3)

(c) inlet manifold air pressure;(3)

- List TEN common log entries, excluding machinery temperatures, pressures and other parameters.(10)

3.(a) State the purpose of a planned maintenance system.(4)

(b) State THREE parameters on which planned maintenance may be based.(3)

(c) State how an approved planned maintenance system can influence classification society requirements.(3)

- With reference to maintenance systems:

(a) state the purpose of scheduled maintenance;(4)

(b) explain why unscheduled maintenance may be required even if a scheduled maintenance system is in operation;(4)

(c) state why breakdowns should be kept to a minimum.(2)

3.

(a) State THREE advantages of using condition monitoring as part of a planned maintenance system.(3)

(b) State THREE examples of criteria that could be used as a basis for condition based maintenance.(3)

(c) State FOUR reasons for keeping records of operating criteria and planned maintenance carried out.

- With reference to maintenance and maintenance systems:

(a) state SIX reasons for keeping records;(6)

(b) explain the advantages of an approved maintenance system.(4)

- With reference to marine diesel oil:

(a) define EACH of the following terms, stating the unit used in EACH:

(i) density;(2)

(ii) viscosity;(2)

(iii) flash point.(2)

(b) excluding the THREE terms listed in part (a), state FOUR items of information contained on a Bunker delivery note.(4)

- With reference to bunkering of marine diesel oil:

(a) state THREE possible consequences of water contamination of the fuel;(3)

(b) state THREE sources of contamination of fuel by water on board a vessel;(3)

(c) describe TWO separate tests which would indicate the presence of water in the fuel.(4)

- With reference to bunkering of marine diesel oil:

(a) explain why the suppliers’ tanks should be dipped prior to and after receiving fuel;(4)

(b) explain what is meant by a letter of protest, and when it must be issued;(4)

(c) state the person responsible for issuing the letter of protest.(2)

- With reference to microbiological contamination of marine gas oil:

(a) state the conditions that must be present for the microbes to live and multiply,(2)

(b) describe the effect of microbiological growth in the fuel;(2)

(c) explain how the contamination may be detected;(2)

(d) state how the risk of contamination may be reduced;(2)

(e) explain how the contamination may be removed.(2)

- With reference to the safe bunkering of marine gas oil fuel:

(a) list SIX actions that should be taken prior to and during the loading;(6)

(b) state FOUR tests to be carried out on the fuel to ensure that it is uncontaminated.(4)

(a) State FOUR possible contaminants that may be present in marine gas oil.(4)

(b) Describe a means of dealing with THREE of the contaminants listed in part (a).(6)

- With reference to the international agreement governing the discharge of oil from ships:

(a) state the name of the International Authority responsible for overseeing the legislation;(1)

(b) state the name of the appropriate regulation;(1)

(c) state what the abbreviation SOPEP stands for;(2)

(d) explain the purpose of a SOPEP;(2)

(e) list FOUR items of information a SOPEP should contain.(4)

- (a) State the main pollutant produced when burning a hydrocarbon fuel.(1)

(b) Explain how the pollutant referred to in part (a) can be reduced.(2)

(c) State what is meant by an ECA.(1)

(d) State the current maximum % sulphur content in marine diesel oil in EACH of the following:

(i) worldwide;(1)

(ii) in a ECA.(1)

(e) Describe how SO, is produced in the combustion process and the effects oxides of sulphur has on the environment.(4)

- List FIVE precautions to be observed before taking on bunkers, stating a reason for EACH precaution.(10)

- With reference to bunkering fuel oil, list the actions that should be taken if a spillage occurs.(10)

5.(a) State the MARPOL Annex number which deals with the disposal of sewage.(1)

(b) With reference to the Annex stated in part (a), state the rules for EACH of the following:

(i) when the sewage is untreated;(2)

(ii) when the sewage is comminuted and disinfected.(2)

(c) Explain why the final discharge from an approved sewage treatment plant is chlorinated before discharge.(2)

(d) Explain how chlorination is carried out and monitored.(2)

(e) State the correct chlorine content of the final discharge.(1)

6.With reference to sewage treatment plants:

(a)

state the purpose of the vent, and explain why it is fitted with a gauze;(3)

(b) explain the difference between aerobic and anaerobic micro organisms;(3)

(c) explain why air is bubbled through the effluent in the aeration tank;(2)

(d) explain why calcium hypochlorite is added to the treated sewage before discharge overboard.(2)

- With reference to sewage treatment plants:

(a) describe the biological operating principle of an aerobic sewage treatment plant, explaining the dangers if a supply of oxygen is not present;(8)

(b) state how a sufficient supply of oxygen is ensured.(2)

- (a) State the IMO regulations for the disposal of sewage.(4)

(b) With reference to aerobic sewage treatment plants, explain EACH of the following:

(i) why air is bubbled through the effluent in the aeration tank;(2)

(ii) why care must be taken over the choice of toilet cleansers used;(2)

(iii) why calcium hypochlorite is added to the treated sewage before discharge overboard.(2)

5.(a) With reference to sewage treatment systems, explain EACH of the following terms:

(i) aerobic;(2)

(ii) anaerobic.(2)

(b) Sketch a Biological Sewage Treatment Plant, labelling the MAIN compartments and indicating the direction of flow through the plant.(6)

- With reference to sewage treatment plants:

(a) explain the difference between black water and grey water;(2)

(b) explain the difference between aerobic and anaerobic micro organisms;(3)

(c) list THREE dangerous gases produced under anaerobic conditions;(3)

(d) explain the dangers of producing the gases listed in part(c) in a confined space.(2)

- (a) State the THREE main stages of a Biological Sewage Treatment Plant.(3)

(b) Describe the operation of a Biological Sewage Treatment Plant, explaining the process carried out in EACH of the stages stated in part (a).(7)

6.(a) With reference to MARPOL Annex IV, explain what is meant by the term sewage.(4)

(b) State the current regulations for the discharge of sewage.(6)

- With reference to sewage treatment plants:

(a) describe the biological operating principle of an aerobic sewage treatment plant, explaining the dangers if a supply of oxygen is not present;(8)

state how a sufficient supply of oxygen is ensured.(2)

- Explain, with the aid of a sketch, how an Aerobic Sewage Treatment plant operates.(10)

Hotel Service Unit 10 Q10 Quiz

- Describe the operation of a Biological Sewage Treatment Plant.(10)

Hotel Service Unit 10 Q11 Quiz

- (a) With reference to food storage rooms:

(i) state, with reasons, the possible danger present in a room used for storing vegetables and fruit;(2)

(ii) state the devices necessary to prevent a person from becoming trapped in a storage room.(3)

(b) State FOUR methods of detecting a refrigeration gas leak.(4)

(c) State the name of the international agreement which stipulates that the production and consumption of compounds that deplete ozone in the stratosphere is phased out.(1)

- With reference to safe storage and handling of refrigerant:

(a) state where the refrigerant gas bottles should be stored;(2)

(b) state the weakest part of the storage bottle;(1)

(c) explain how it can be determined if refrigerant has been leaking from gas bottles;(1)

(d) state the TWO methods of recharging a refrigeration system, stating where the connection to the system should be made for EACH method;(4)

(e) state how excessive refrigerant should be removed from the system without infringing MARPOL regulations.(2)

- With reference to refrigeration plants, describe the effects of EACH of the following, stating remedial actions to be taken in EACH case:

(a) undercharge of refrigerant;(3)

(b) air in the system;(3)

water or moisture in the system.(4)

- With reference to refrigeration plant;

(a) state THREE indications of a loss in refrigerant charge;

(b) state THREE methods of detecting the location of the source of leakage;

(c) describe a safe method of bringing the gas charge back to its normal working level.

- With reference to refrigeration systems:

(a) state the THREE basic principles of refrigeration;(3)

(b) sketch a direct expansion free standing mechanical refrigeration system, labelling the MAIN components and indicating where EACH of the three principles stated in part (a) occurs.(7)

- (a) Sketch a vapour compression refrigeration system, labelling the main components.(5)

(b) Indicate the refrigerant conditions at the salient points on the sketch in part(a).(5)

- (a) State FIVE properties of a refrigeration oil.

(b) Describe the operation of an Oil Separator in a refrigeration system.

- (a) Sketch a thermostatically controlled expansion valve for a vapour compression refrigeration system, labelling all components.

(b) Describe the operation of the valve sketched in part (a).

7.(a) State THREE functions of air conditioning.

(b) With referance to air conditioning, explain EACH of the following:

(i) absolute humidity;

(ii) relative humidity;

(iii) dew point.

- With reference to Marine Air Conditioning Systems, explain EACH of the following expressions:

(a) wet bulb temperature(2)

(b) dry bulb temperature;(2)

(c) comfort zone;(2)

(d) psychrometric chart;(2)

(e) relative humidity.(2)

- With reference to the risk of legionella bacteria in air conditioning plants:

(a) state FOUR main areas which are considered to be a breeding ground for the bacteria, outlining a reason for EACH;(8)

(b) describe how the risks of the existence of the bacteria can be reduced.(2)

- With reference to reverse osmosis plants:

(a) describe the sea water pre-treatment process before the water enters the membrane modules;(6)

(b) describe how the purity of the permeate is measured;(3)

(c) state the limits of impurity in the permeate when produced to World Health Organisation Standards.

7.

(a) Describe, with the aid of a sketch, a reverse osmosis plant, from feed water inlet, to product tank, labelling ALL components and showing the position in the system of the monitoring instruments.(7)

(b) Describe the feed water pre-treatment process before the water enters the spirally wound membrane modules.(3)

7

. (a) Describe, with the aid of a sketch, the operation of the silver ion method of water sterilisation.(6)

(b) Describe how Ultra Violet Light can be used to kill bacteria in potable water.(2)

(c) Explain the disadvantages of using Ultra Violet Light as a method of sterilisation, stating how this may be overcome.(2)

- With reference to reverse osmosis plants:

(a) explain the treatment that the feedwater undergoes to prevent blockage of the membranes;(3)

(b) describe how the purity of the water is measured and protected, stating the limits on purity set by the World Health Organisation;(5)

(c) outline the further treatment the permeated water undergoes before it can be used for domestic purpose.(2)

- Describe, with the aid of a sketch, the construction of a spirally wound membrane suitable for use in a Reverse Osmosis water making plant, identifying ALL component parts.(10)

- Explain, with the aid of sketches, the principles of reverse osmosis as a method of producing fresh water.(10)

- Sketch a line diagram of a single pass reverse osmosis plant.(10)

8.(a) State TWO methods of producing fresh water on board an ocean going vessel.(2)

(b) State TWO methods of killing the bacteria which may be present in the water.(2)

(c) Explain the reasons for adding hydrated lime to water produced on board an ocean going vessel.(3)

(d) Outline the procedure to be followed before a fresh water tank is brought back into service.(3)

- With reference to water treatment:

(a) state the treatment required for fresh water taken on from ashore;

(2)

(b) state FOUR properties required for water used for domestic purposes, describing how this may be achieved in EACH case.(8)

- With reference to fresh water treatment:

(a) describe the process for superchlorinating the fresh water system, stating relevant periods, times, and chlorine levels;(6)

(b) explain what is meant by copper staining and the treatment required to prevent it.(4)

6. (a) State THREE types of micro-organisms that may exist in water.(3)

(b) Describe, with the aid of a sketch, the operation of a Silver Ion Sterilizer.(7)

- With reference to portable fire extinguishers:

(a) describe the examination and testing of portable fire extinguishers as specified in the UK and Internatinal legislation.

(6)

(b) state the classes of fire that Dry powder extinguishers may be safely used;

(2)

(c) describe the operation of a portable CO, fire extinguisher.

(2)

- Define EACH of the following, stating an example in EACH case where a fire could be caused:

(a) spontaneous combustion;

(4)

(b) flash point;

(3)

(c) auto ignition temperature.

(3)

- (a) Define EACH of the following:

(i) Flash Point;

(ii) Ignition Point

(iii) Auto Ignition Temperature.

(2)

(2)

(2)

(b) Explain the requirements for the discharge of CO₂ of a machinery space fixed firefighting installation with regard to volume and time.

(4)

- With reference to a machinery space carbon dioxide smothering system:

(a) state the regulation regarding the rate of flooding with respect to time;

(4)

(b) state the precautions to be taken before activating the system.

(6)

- (a) Explain the need for fitting, location, and operation of an engine room fire main isolation valve.

(4)

(b) State the type of valve used in part (a).

(1)

(c) Describe, with the aid of a sketch, the construction of a sprinkler head.

(5)

- (a) Describe, with the aid of a sketch, how a pressurised system sprinkler head is constructed.

(5)

(b) Explain the operation of the sprinkler head and bulb assembly described in part (a), stating how the alarm is initiated.

(5)

- Sketch a line diagram of an automatic sprinkler system, labelling the MAIN components.

(10)

9.

(a) State FIVE monthly checks which should be carried out on fire fighting equipment.

(5)

(b) State FIVE yearly checks which should be carried out on fire fighting equipment.

(5)

9. Describe, with the aid of a sketch, a multiple bottle CO, gas system suitable for the protection of machinery spaces.

(10)

- Describe, with the aid of a sketch, the construction and operation of a thermistor type rate of rise heat detector.

(10)

Hotel Service Unit 15 Q10 Quiz

List the important operations that should be included when organising fire drills.

(10)

Hotel Service Unit 15 Q11 Quiz

8.(a) Describe, with the aid of a sketch, the method of attachment of a Bilge Keel to a vessel’s hull, explaining the reason for the longitudinal position of the bilge keel, relative to the hull.(7)

(b) State the advantages and disadvantages of fitting a bilge keel compared with other methods of stabilisation.(3)

- With reference to the motion of a vessel in the water:

(a) list the SIX degrees of freedom, describing the meaning of EACH term;(6)

(b) sketch the position of a bilge keel, describing how it reduces vessel motion.(4)

8.(a) State TWO types of Tank Anti-Roll Stabiliser systems.(2)

(b) State the advantages and disadvantages of a stabilising tank system compared to fin stabilisation.(8)

- Describe, with the aid of a sketch, the construction and operation of an Active Controlled Tank roll damping system.(10)

- Describe, with the aid of a sketch, an active tank stabilisation system.

(10)

- Explain, with the aid of a sketch, the hydrodynamic operation of an Active Fin Stabilizer.(10)

With reference to MARPOL Annex V, garbage record book:

(a) state the type of vessel to which the regulation applies;(1)

(b) list the NINE categories into which garbage is grouped for the purpose of the garbage record book.(9)

- With reference to MARPOL Annex V:

(a) list the THREE recognised complimentary garbage handling techniques;(3)

(b) describe the basic requirements of a Garbage Management Plan;(5)

(c) define what is meant by E-Waste.(2)

- With reference to Oily Water Separators (OWS) and the pumping of bilges, explain EACH of the following:

(a) why a positive displacement pump is preferable to a centrifugal pump as the main bilge pump;(2)

(b) why it is important that the flow rate to the separator is not exceeded;(2)

(c) why the discharge overboard line should be higher than the OWS;

(2)

(d) how detergents used for bilge cleaning can affect the operation of the separator;(2)

(e) why an air release is fitted to the top of the shell of the OWS,(2)

- With reference to Annex 1 of the MARPOL convention, state EACH of the following:

(a) the appropriate system to be fitted on a vessel 400GRT or above;(4)

(b) the documentation required, explaining why it is required;(2)

(c) the information to be recorded when pumping bilges overboard through an oil water separator.(4)

- With reference to Oily Water Separators and the pumping of bilges, explain the purpose of EACH of the following:

(a) a bilge holding tank;(2)

(b) an oil drain tank;(2)

(c) an oil content discharge monitor;(2)

(d) a vacuum breaker;(2)

(e) an oil detection probe.(2)

- With reference to the use of Oily Water Bilge Separators:

(a) state, with reasons, the type of pump which should be used;(3)

(b) explain the effect of the bilge water feed rate on the performance;(3)

(c) explain the purpose of EACH of the following:

(i) a bilge holding tank;(2)

(ii) an oil content discharge monitor.(2)

- Describe, with the aid of a sketch, a single stage static Oily Water Separator designed to meet MARPOL Annex I requirements.(10)

3.(a) State the SIX MARPOL annexes which are currently in force.(6)

(b) With reference to MARPOL Annex VI and Oxides of Nitrogen (NO), state which engines have to comply with the legislation.(2)

(c) State TWO other pollutants that Annex VI is designed to limit.(2)

- With reference to ocean going vessels, define EACH of the following:

(a) trim;(1)

(b) freeboard;(1)

(c) camber;(1)

(d) length between perpendiculars;(1)

(e) length overall;(1)

(f) sheer;(1)

(g) stem;(1)

(h) draft marks;(1)

(i) draft;(1)

(j) depth;(1)

- a State the meaning of EACH of the following terms in relation to a vessel’s size:

(i) gross tonnage;(2)

(ii) net tonnage;(1)

(iii) lightweight;(2)

(iv) deadweight;(2)

(v) displacement.(2)

(b) State the relationship between Lightweight, Deadweight and Displacement.(1)

- With reference to a vessel’s structure, explain the meaning of EACH of the following terms:

(a) beam;(2)

(b) frame;(2)

(c) girder,(2)

(d) beam knee;(2)

(e) stringer.(2)

- Explain the meaning and purpose of EACH of the following terms:

(a) flare;(2)

(b) bulwark;(2)

(c) coaming;(2)

(d) freeing port;(2)

(e) scupper.(2)

- Explain the meaning of EACH of the following terms:

(a) LOA;(2)

(b) displacement;(2)

(c) load line;(2)

(d) draught;(2)

(e) breadth.(2)

- With reference to the construction of a vessel, state the meaning of EACH of the following terms:

(a) sheer;(2)

(b) freeboard;(2)

(c) moulded depth;(2)

(d) moulded draft;(2)

(e) flare.(2)

- Explain EACH of the following types of motion:

(a) roll;(2)

(b) pitch;(2)

(c) yaw;(2)

(d) surge;(2)

(e) heave.(2)

- With reference to the use of Oily Water Bilge Separators, explain the meaning of EACH of the following terms:

(a) turbulent flow;(2)

(b) emulsion;(2)

(c) maximum flow rate;(2)

(d) coalescence;(2)

(e) interface.(2)

10. (a) Explain the meaning of EACH of the following terms:

(i) camber;(2)

(ii) sheer.(2)

(b) Describe how EACH of the terms explained in part (a) improve seaworthiness.(6)

- Describe the immediate action that should be taken in the event of EACH of the following occurring, stating a possible consequence if the action is not carried out:

(a) a high pressure fuel leak on the main engine;(4)

(b) severe vibration from the main engine;(3)

(c) high cooling water temperature alarm on generator engine.(3)

(a) Explain what is meant by the term Machinery Abstract.(4)

(b) List SIX items which would be recorded in a typical Machinery Abstract.(6)

- (a) With reference to ship construction, define a bulkhead.(2)

(b) State the functions of bulkheads.(8)

- Describe the functions of a watertight bulkhead. (10)

- State the purpose of infra red photography, explaining where it could be used as part of a condition monitoring programme.(10)

6.(a) State SIX advantages of controllabe pitch propellers.(6)

(b) State FOUR disadvantages of controllable pitch propellers.(4)