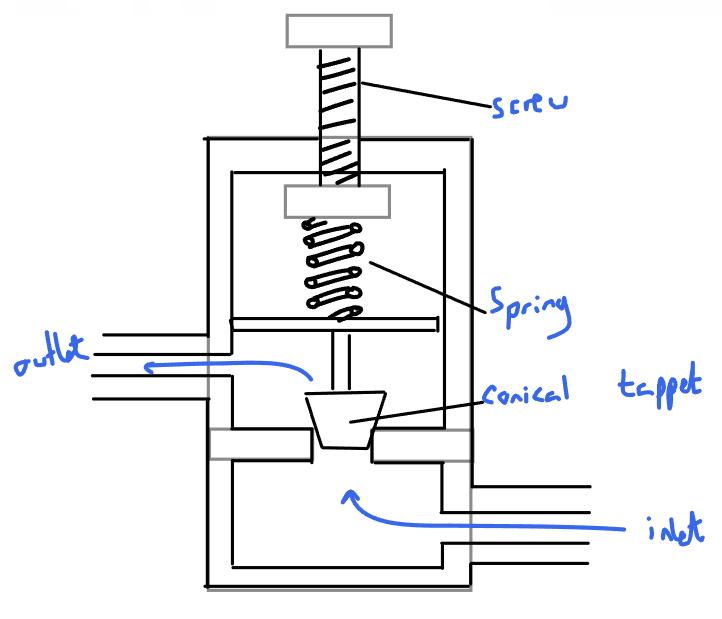

For supplying control air from the main starting air supply in a pneumatic control system, a pilot-operated pressure reducing valve is the most suitable option. Here’s a breakdown of its features and why it’s well-suited for this application:

Pilot-Operated Pressure Reducing Valve:

This type of valve uses a separate pilot section to control the main valve, offering precise and stable pressure regulation. Here’s how it works:

- Main Valve and Seat: The main valve consists of a spool or poppet that controls the flow of air from the high-pressure (starting air) inlet to the low-pressure (control air) outlet. The valve seat provides a seal against the main spool or poppet.

- Pilot Section: The pilot section has a small diaphragm or piston that senses the downstream (control air) pressure. It is typically connected to the outlet of the main valve.

- Pressure Regulation: When the downstream pressure falls below the desired set point, the pilot section senses the decrease. This triggers a signal (pneumatic or mechanical) that opens the main valve slightly, allowing more high-pressure air to flow and increase the downstream pressure.

- Pressure Feedback and Stability: As the downstream pressure rises towards the set point, the pilot section detects the increase and closes the main valve slightly, maintaining a constant downstream pressure. This feedback loop ensures stable and precise pressure regulation.

Suitability for Supplying Control Air:

- Accurate Pressure Regulation: Pilot-operated valves offer high accuracy in maintaining the desired control air pressure, crucial for reliable operation of pneumatic actuators.

- Wide Pressure Range: These valves can handle a wide range of upstream (starting air) pressures while precisely regulating the lower downstream (control air) pressure.

- Stable Operation: The pilot section’s feedback loop ensures stable pressure output, even with fluctuations in the upstream pressure or downstream demand.

- Dirt Tolerance: Pilot-operated valves can be relatively tolerant of dirt particles compared to some other pressure reducing valve designs.

Additional Considerations:

- Material Selection: The valve body and internal components should be made of materials compatible with the compressed air system and any lubricants used.

- Flow Capacity: Select a valve with a flow capacity sufficient to meet the maximum required control air demand in your system.

- Pressure Relief Option: Some models may have a built-in pressure relief valve to protect the downstream system from excessive pressure in case of malfunction.

By choosing a pilot-operated pressure reducing valve with the appropriate specifications, you can ensure a reliable and stable supply of control air for your pneumatic control system.