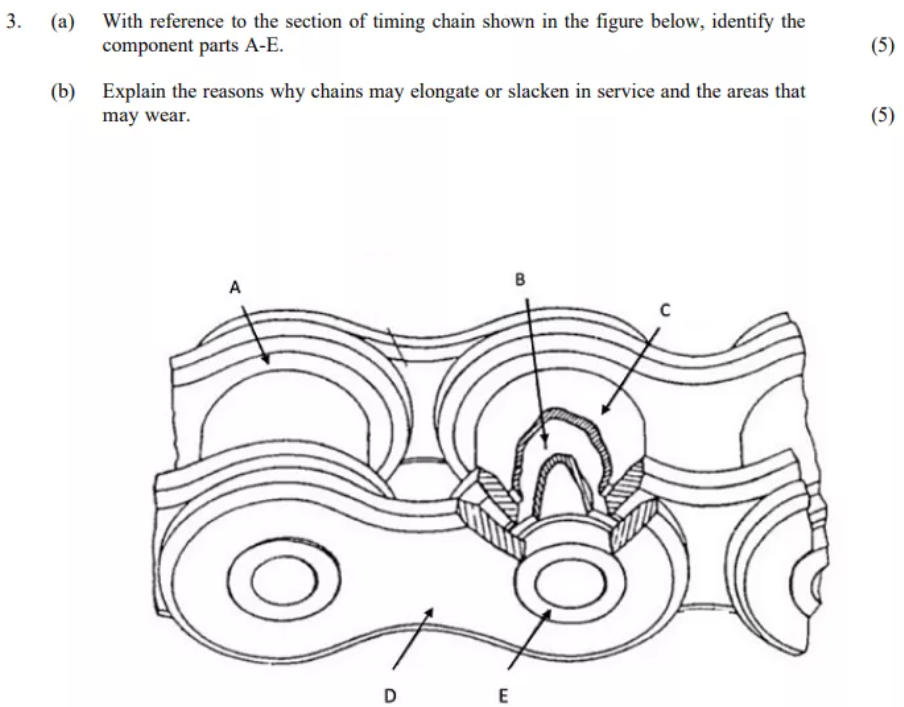

(a) With reference to the section of timing chain shown in the figure below, identify the component parts A-E.

(5)

(b) Explain the reasons why chains may elongate or slacken in service and the areas that may wear.

(5)

Components of a Timing Chain Link

A timing chain link is typically composed of the following components:

- Outer Plates: These are the flat, rectangular plates that form the exterior of the chain. They provide strength and durability.

- Inner Plates or Bushings: Located between the outer plates, these components provide support for the pins. 1. Roller chain – Wikipedia en.wikipedia.org

- Rollers or Bushings: These cylindrical components surround the pins and reduce friction as the chain rotates. 1. Understanding the Components of Roller Chain | Power Transmission and Conveyance www.peerchain.com

- Pins: These metal pins connect the inner and outer plates, allowing the chain to flex and move.

- Rivets or Welds: These secure the inner and outer plates to the pins, forming a strong and durable link.

These components work together to create a chain that is strong, flexible, and resistant to wear, ensuring reliable operation of the engine’s timing system.

Opens in a new windowshopdap.com

timing chain components

Chain Elongation and Wear

Reasons for Chain Elongation

Chain elongation, often referred to as “stretch,” is not actually an increase in the length of the chain links themselves, but rather a result of wear on the chain’s components.

- Wear of rollers and bushings: The primary cause of elongation is the wear of the rollers and bushings within the chain links. This wear increases the distance between the rollers on a pin link, effectively lengthening the chain.

- Pin and bushing wear: Over time, the pins and bushings within the chain links also wear, contributing to chain elongation.

- Improper lubrication: Inadequate lubrication accelerates wear on chain components, leading to premature elongation.

- Overloading: Exceeding the chain’s rated load capacity can cause excessive wear and premature elongation.

Areas of Wear

- Rollers: The cylindrical components that interact with the sprocket teeth experience wear due to friction and load.

- Bushings: Located within the chain links, these components support the pins and undergo wear.

- Pins: The metal pins connecting the chain links can wear due to friction and bending stresses.

- Outer plates: While less prone to wear compared to other components, the outer plates can experience abrasion and fatigue.

- Sprockets: The sprocket teeth also wear due to contact with the chain, affecting chain life and performance.

Common Components of a Timing Chain System

Common Components of a Timing Chain

A timing chain system consists of several essential components working together to synchronize the crankshaft and camshaft:

- Timing chain: The core component, made of metal links, that drives the camshaft from the crankshaft. 1. What is a Timing Chain? How to Manage Timing Chain Problems By Lee Jones | YMF Car Parts www.ymfcarparts.co.uk

- Crankshaft sprocket: The toothed gear attached to the crankshaft, where the timing chain engages.

- Camshaft sprocket: The toothed gear attached to the camshaft, driven by the timing chain.

- Chain tensioner: A device that maintains optimal tension on the timing chain, preventing slack and wear. 1. Chain tensioners – variants and function – repxpert www.repxpert.com

- Chain guides: Components that guide the timing chain and prevent it from jumping off the sprockets. 1. Timing Chain Replacement – Part Info www.partinfo.co.uk

- Oil pump sprocket: In many engines, the oil pump is driven by the timing chain through a separate sprocket.

These components work together to ensure precise timing of the engine’s valves for optimal performance and efficiency.

1. Demystifying Timing Chains: The Backbone of Your Engine’s Timing System – D’Addario’s Auto Service Inc – Auto Repair East Hartford CT

Opens in a new windowshopdap.com

timing chain components